In this day and age where the ROLL UP method of wearing jeans is popular, you may have heard of a term called: selvedge jeans. If you are a denim lover, it should not be difficult to find that selvedge jeans are better than non-denim jeans. Selling ear jeans are generally expensive, and of course, selvedge denim is also extremely popular, BUT WHY?

To answer The question of why selvedge jeans are so expensive requires a clear explanation of what selvedge jeans are. Everyone knows that the fabric required to make jeans is called Denim, and the difference between selvedge jeans and non-selvedge jeans lies in the different raw materials. , making selvedge jeans requires a raw material called “selvedge denim”. This raw material was produced by the ancient shuttle looms decades ago. The denim produced by the shuttle looms The edges of the cloth have been wrapped, English

Selvedge (Selfedge, Selvage) That’s it, the literal translation is “self-wrapping”.

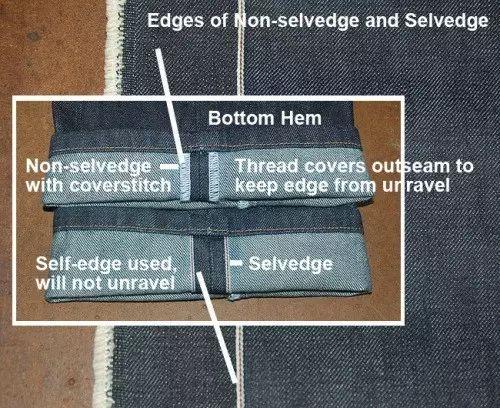

What needs to be said about “edging” is: “edging” is called “ear”, which visually looks like a trace, because most of this trace They are all red, which gives rise to the term “red ears”. In fact, there are also ears of other colors, such as green ears, blue ears, purple ears and even colored ears.

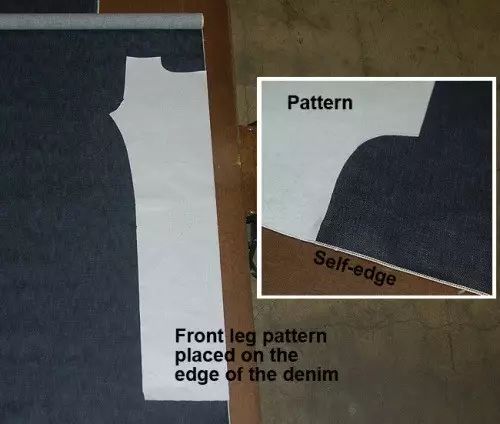

Now everyone understands what “red-eared denim” is. To be honest, the denim produced with shuttle looms decades ago is still the same today. The selvedge denim fabric was a very common denim fabric at that time. However, due to the low production efficiency of the shuttle loom and the high labor intensity of the weavers, the labor cost was naturally high. The width of denim fabric produced by shuttle looms is generally 31 inches to 34 inches wide. Due to the width limitation, merchants generally try to use the corners of this fabric for ease of use. For example, as you can see from the picture below, merchants How do you start cutting the edge of selvedge denim to make the fabric of jeans legs:

After the pants are sewn, you can see the selvedge denim by opening the legs. The hemming is also commonly referred to as selvedge jeans. It is also very simple to distinguish selvedge jeans from non-selvedge jeans. You can tell at a glance after ROLL UP (roll up the trouser legs). You can also intuitively see that selvedge jeans are better. A little more flavor:

Although non-selvedge jeans generally account for a much larger share of the market, there are many famous cow brands that also have selvedge jeans and “original jeans.” cattle” products, such as

Levi’s, Lee, 7 For All Mankind, PRPS, EVISU, Nudie

Wait, of course, when it comes to the best selvedge jeans, Japan takes the lead. Since Japan bought back the ancient shuttle looms from the United States to produce selvedge jeans, after decades of improvement and precipitation, Japan’s Red-ear jeans, or Japanese jeans, have become a recognized global

NO.1, this is why many brands like to use MIJ – Made in Japan (Made in Japan) as a gimmick to raise prices.