The quality of chemical fiber refers to an indicator that is decisive for the use value of fiber products. Physical performance indicators, including fiber length, fineness, density, gloss, hygroscopicity, thermal properties, electrical properties, etc.; mechanical performance indicators, including breaking strength, elongation at break, initial modulus, resilience and resistance to multiple deformations. etc.;

Stability performance indicators, including stability to high and low temperatures, stability to light and atmosphere, stability to light and atmosphere, stability to chemical reagents and stability to microorganisms etc.; processing performance indicators, including fiber cohesion, electrical resistance and dyeability, etc.; additional quality indicators of short fibers, including fiber length, crimp, fiber defects, etc.

1. Fineness

Fineness is the degree of fiber thickness, which is divided into two types: direct index and indirect index. Direct indicators are generally expressed by the diameter and cross-sectional area of the fiber. Since the cross-sectional area of the fiber is irregular and difficult to measure, there are not many direct indicators used to express its thickness, so indirect indicators are often used. The indirect index is determined by fiber quality or length, that is, the quality (fixed length system) or length (fixed weight system) of the fiber when the length or weight is fixed. In the chemical fiber industry, it is usually based on the fiber quality per unit length, that is, the thread Density (linear

density) (fineness) expression, the following three expression methods are commonly used.

1. Tertex (tex) or decitex (dtex)

Tex or decitex is the international system of units. The mass (g) of a 1000m long fiber is called tex; 1/10 of it is decitex. Because the fiber fineness is relatively small, the numerical value is smaller when expressed in terms of decitex, so the fineness of the fiber is usually expressed in decitex.

For the same kind of fiber (that is, when the density of the fiber is constant), the smaller the special number, the finer the single fiber, the softer the hand, the softer luster, and the easier deformation processing.

2. Denier

The mass (g) of a 9000m long fiber is called denier. For the same fiber, the smaller the denier, the thinner the single fiber. Denier is a non-statutory unit of measurement for linear density. 1den=9tex.

3. Metric count (Nm)

Metric count is referred to as public count, which refers to the length (m) of fiber per unit mass (g). For the same fiber, the higher the count, the finer the fiber. Metric counts are non-statutory units of measurement for linear density.

The values of tex or decitex, denier and count can be converted to each other, and the relationship is as follows.

Denier*Number=9000

Special number*Number=1000

Denier=9*Special number

Min. Special number = 10 * special number

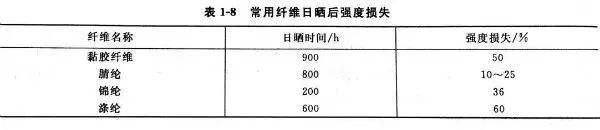

The linear density indicators of various fibers are shown in Table 1-4.

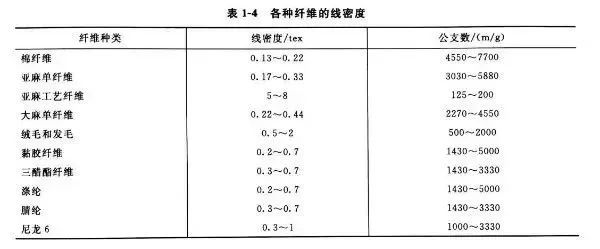

2. Density

The density of fiber refers to the mass of fiber per unit volume, the unit is g/cm³. The densities of various fibers are different. Among the main chemical fiber varieties, polypropylene has the smallest density and viscose fiber has the highest density. The densities of the main textile fibers are shown in Table 1-5.

3. Hygroscopicity

The hygroscopicity of fibers refers to the water absorption rate of fibers under standard temperature (20°C, 65% relative humidity) conditions, and is generally expressed by two indicators.

Moisture regain: the ratio of the weight of water contained in the fiber to the dry weight of the fiber. That is, moisture regain = weight of moisture contained in the sample/weight of dry sample * 100%

Moisture content: the ratio of the weight of moisture contained in the fiber to the wet weight of the fiber. That is, the moisture content = the weight of the moisture contained in the sample / the weight of the undried sample * 100%

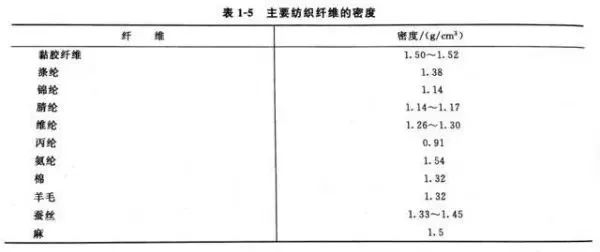

The hygroscopicity of various fibers is very different, and the hygroscopicity of the same fiber also depends on the ambient temperature. , there are great changes depending on the humidity. In order to meet the needs of weight calculation and price verification, unified regulations must be made on the moisture regain of various textile materials, which is called the official moisture regain. The moisture regain of various fibers under standard conditions and the official moisture regain stipulated in our country are shown in Table 1-6 .

As can be seen from Table 1-6, the moisture regain rate of natural fibers and regenerated fibers is higher, while the moisture regain rate of synthetic fibers is lower. Among them, the moisture regain rate of polypropylene, chlorine fiber and ethylene fiber is zero.

Hygroscopicity affects the processing performance and performance of the fiber. Fibers with good hygroscopicity reduce friction and static electricity, making them comfortable to wear. For synthetic fibers with poor hygroscopicity, modification methods can be used to improve their hygroscopicity.

4. Tensile properties

Fiber materials will be subjected to stretching, bending, compression, friction and torsion during use, resulting in different deformations. The main external force that chemical fibers are subjected to during use is tension. The bending properties of the fibers are also related to their tensile properties. Therefore, the tensile properties are the most important mechanical properties of the fibers. There are three main indicators to measure the tensile properties of fibers: breaking strength, elongation at break, and initial modulus.

1. Breaking strength

Relative strength is commonly used to express the breaking strength of chemical fibers. That is, the ratio of the maximum load that the fiber can withstand until it breaks under the action of continuously increasing load and the linear density of the fiber. The units are N/tex (N/tex) and centiN/tex (cN/tex).

Breaking strength is an important indicator that reflects fiber quality. The breaking strength is high, and the fiber is not easy to break or wind around during processing. The fastness of yarn and fabric is high, but the breaking strength is too high.�Strong fiber>Cupramine fiber>Viscose fiber>Acetate fiber>Glass fiber.

11. Light resistance and stability

Stability to sunlight and atmospheric effects is one of the stability indicators of the fiber. It is also called weather resistance. It is the resistance of the fiber to weather conditions. A measure of the ability to vary performance.

Lightfastness refers to the mechanical properties of the fiber that remain unchanged after being exposed to light. Stability to atmospheric effects refers to the performance of fibers that do not undergo degradation or photo-oxidation or color changes after being exposed to light, oxygen, heat and moisture in the air for a long time.

The light resistance of chemical fibers is related to the composition of fiber molecular segments, the formation of main chain bonds and cross-linking bonds, the vibration energy and conversion of molecular groups, the aggregation structure of the fiber, and the intensity of light radiation. , the irradiation time is related to the wavelength.

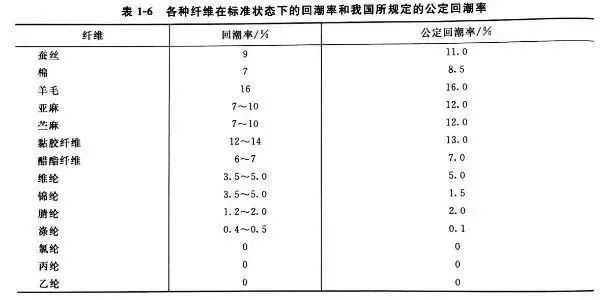

Climate conditions cause changes in fiber properties, mainly due to sunlight and oxygen in the air. Therefore, improving the stability of fiber light resistance to atmospheric effects is to improve its light stability and oxygen stability. The strength loss of commonly used fibers after sunlight is shown in Table 1-8.