Before processing cotton, wool, and silk fibers into fabrics, the process of using a combing machine to remove impurities and thick and short fibers from the fibers is called combing. The texture, washability and durability of the fabric produced through this process are greatly improved compared to carded fabric.

In cotton spinning, products with fine fineness and high quality requirements and special yarns, such as extra fine yarns, tire cords, etc., usually use the combed spinning system; while In woolen, linen and silk spinning, due to their long fiber length and poor length uniformity, combing is generally used to remove short fibers and reduce length unevenness.

Purpose

1. To eliminate short lint in the raw sliver, increase the average length and uniformity of the fiber, and improve the results. The yarn is dry, reducing yarn hairiness and improving yarn strength.

2. Remove residual neps and impurities in the card sliver to reduce yarn breakage and yarn defects, and improve the appearance quality of the yarn.

3. Further straighten, parallelize and separate the fibers to improve the evenness, strength and gloss of the yarn.

4. Make combed cotton sliver with uniform sliver, which is convenient for the next process.

The yarn strength can be increased by 10%~20%; the number of neps and impurities can be reduced by 50%~60%; the evenness and gloss can be significantly improved; combed yarn It has high thread strength, less knots, even lines and good gloss.

Task

1. Make small rolls for easy processing by combing machine.

2. Improve the straightness, parallelism and separation of fibers in small rolls to reduce damage to fibers and combing needles during combing. And reduce the content of long fibers in combed noil, saving cotton.

Quality requirements for small rolls

The longitudinal and transverse structures of small rolls must be uniform so that the cotton layer can be Combing with good grip;

The small rolls are well formed, have large capacity, and do not stick to the rolls.

Machinery

There are four types of preparation machinery currently used at home and abroad: pre-draw frame (drafting), draw frame Winding machine (rolling), doubling machine (drafting, doubling) and strip doubling and winding combined machine.

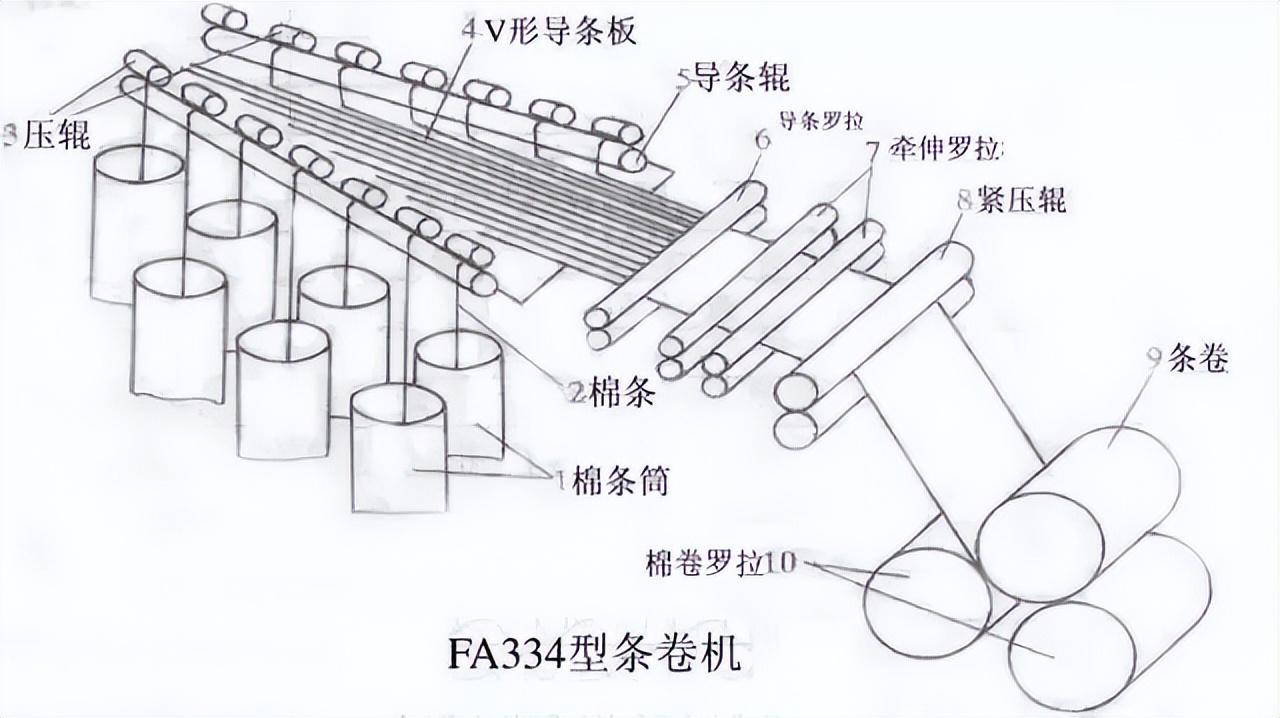

Strip rolling machine

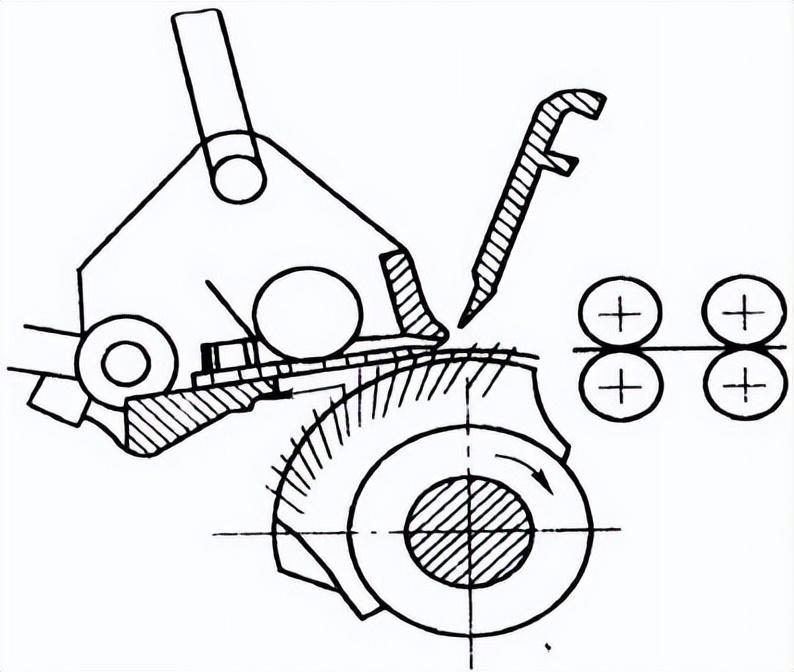

Picture

1. Under the guidance of the guide roller and the guide pressure roller, 20~24 cotton slivers are rotated 90° on the V-shaped platform and arranged in parallel.

2. The sliver enters the drafting device under the guidance of the guide roller.

3. The drawn cotton layer is pressed by a tight roller to prevent sticking.

4. The cotton layer is driven by the cotton roll roller to make small rolls.

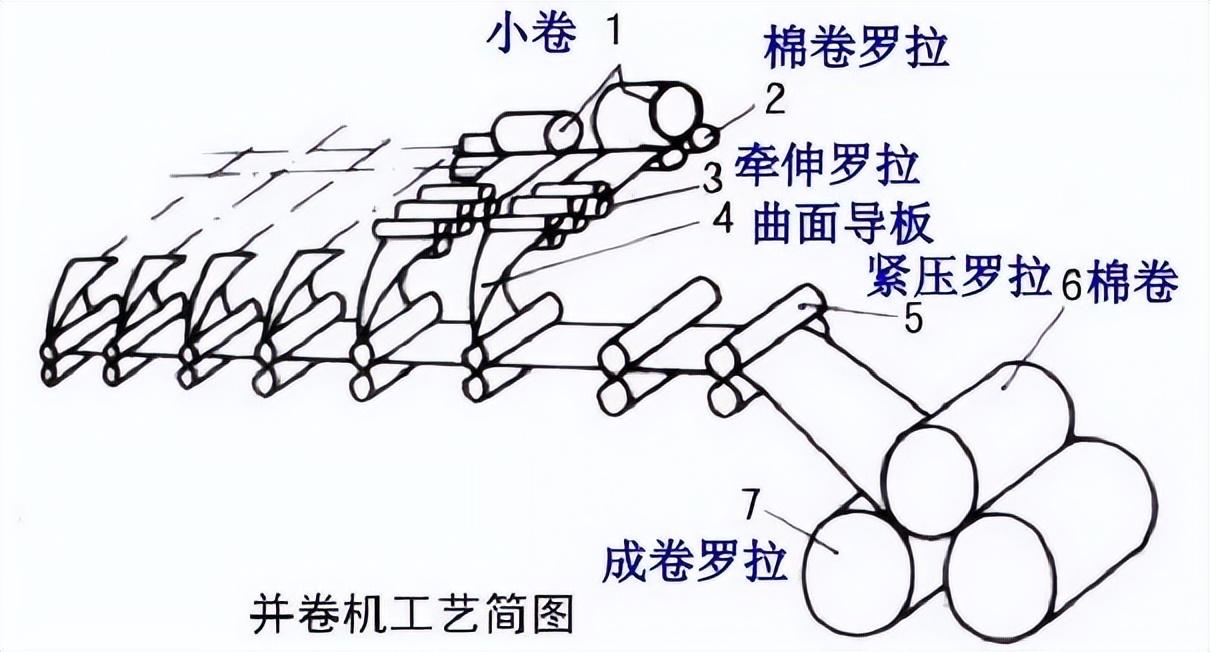

Parallel winding machine

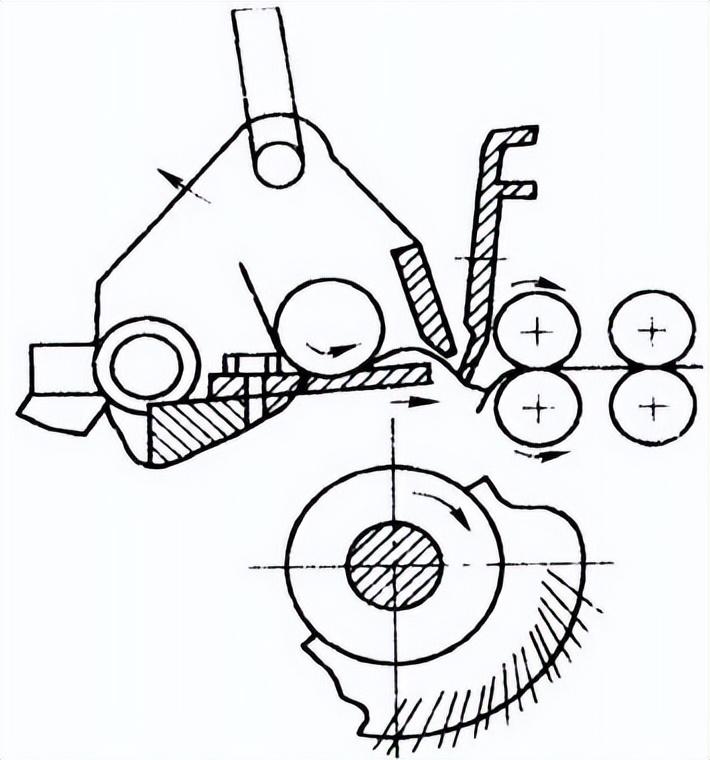

Picture

1. The 6 combed small rolls enter the drafting device respectively;

2. The drafted cotton web is turned 90° through the smooth curved guide plate and is placed on the carding platform. The upper 6 layers are superimposed on each other;

3. Enter the pressing roller, and then roll it into a small combed roll by the rolling roller.

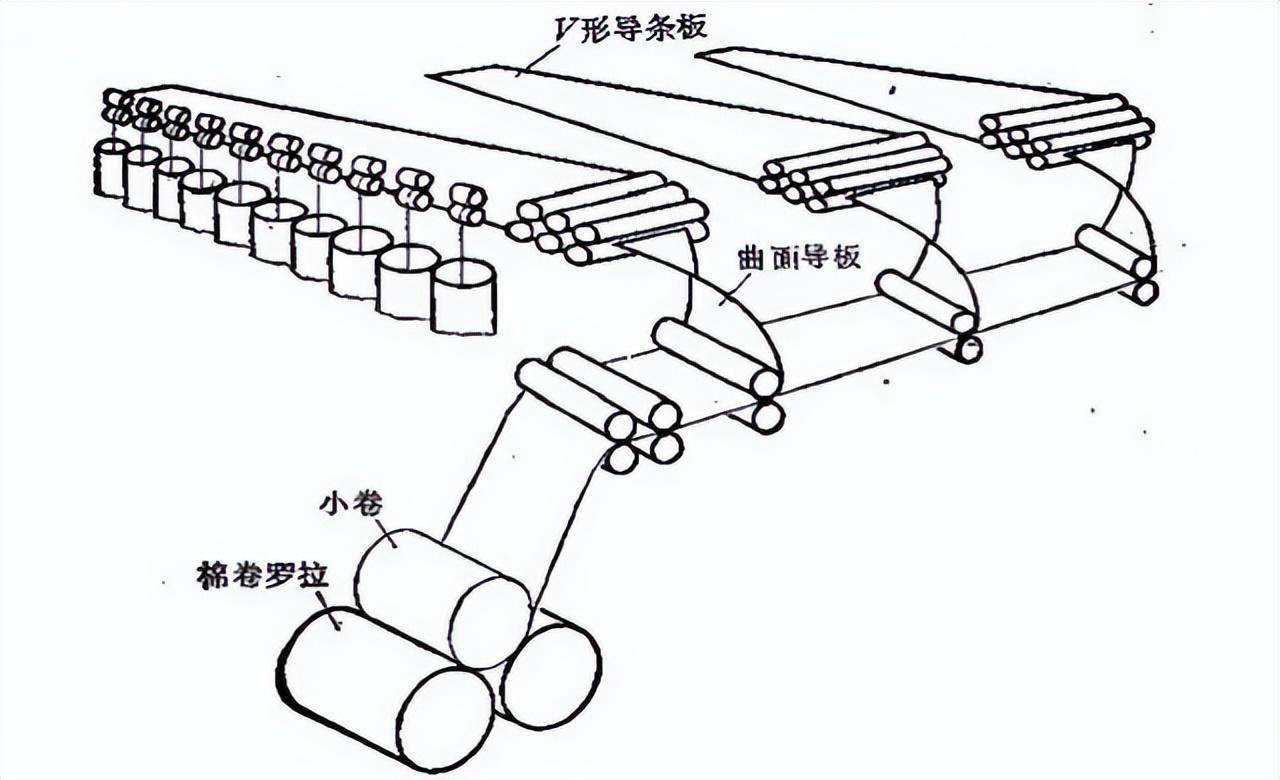

Strip parallel and coil combined machine

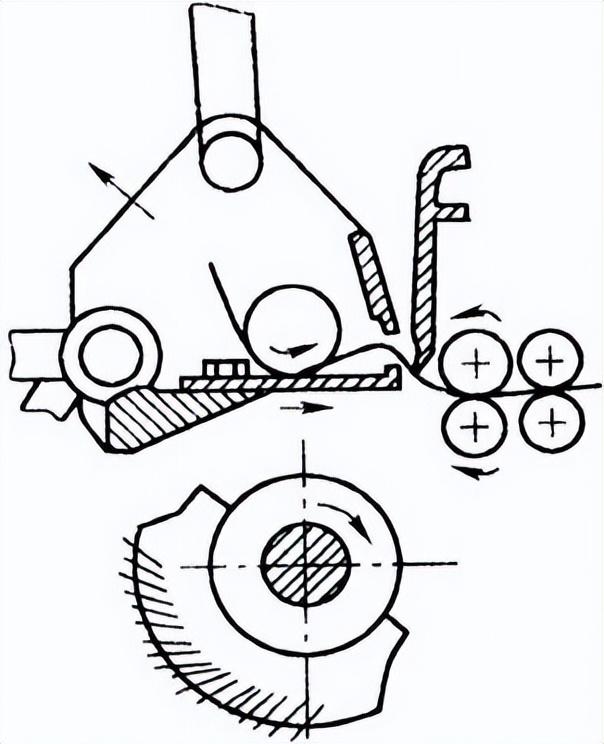

Picture

1. The feeding part is divided into three groups, each group has 16 to 20 slivers fed through the guide roller, and each group of cotton slivers is drawn into a cotton web through the V-shaped guide plate and the drafting device;

2. After the cotton web is output, it is passed through the curved guide plate, turned 90° and stacked on the platform;

3. Pressed by the pressure roller After that, the cotton roll is wound into small rolls.

Pictures

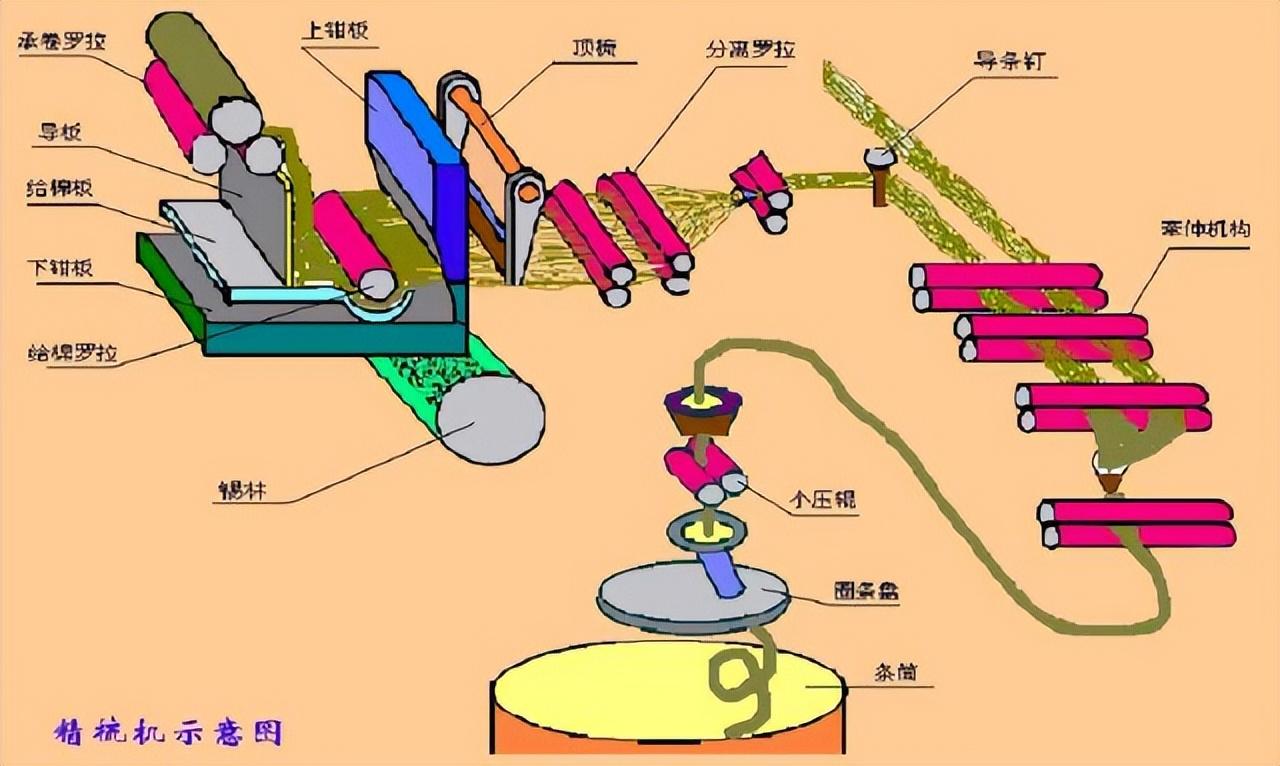

△ Combing process

1. The movement coordination relationship of the main parts on the combing machine is indicated by a dial. The disc is installed on the combing machine and rotates synchronously with the cylinder. It is generally called an indexing disc. The indexing disc is divided into 40 equal parts along the circumference, and each equal part is 9°, which becomes an index.

2. One clamp (one motion cycle)

The panel of the combing machine reciprocates once, or Cylinder turns around.

3. A movement cycle of the combing machine can be divided into four stages:

Cylinder carding stage.

The preparation stage before separation.

Separation and engagement stage.

The preparation stage before cylinder carding.

① Cylinder combing stage

Picture

Movement of main components:

Clamp: swing back and then forward, the jaws are closed;

Tin Lin: combing the cotton bush;

Top comb: swinging back and then forward (not involved in carding);

Separating roller : In a basically static state.

② �Preparatory stage before departure

Pictures

Movement of main components:

Clamp: continue to swing forward, the jaws gradually open;

Cylinder: continue to rotate without combing the cotton;

Top comb: continue to swing forward and start to contact the cotton;

Separating roller: start to reverse from static to reverse the cotton web After entering the machine, it is ready to be combined with the fiber bundles sent by the clamping plate.

③ Separation and engagement stage

Picture

Movement of main components:

Clamp: continue to swing forward, and the jaws open to the maximum;

Cylinder : Continue to rotate without combing the cotton clump;

Top comb: Continue to swing forward to comb the cotton clump;

Separating roller : Rotate clockwise, pull out the fibers sent by the clamping plate, and overlap them at the end of the original cotton web for output.

④ Preparatory stage before cylinder combing

Picture

Movement of main components:

Clamp: back swing, jaws gradually close;

Cylinder: continue to rotate, the first row of needles is close to the cotton bush;

Top comb: gradually separate from the cotton bush;

Separating roller: Continue to output the cotton web in a clockwise direction, and gradually become stationary.

The difference between high-combination, combed, semi-combed and carded

High-quality cotton: refers to the cotton grade is relatively high , which means that the raw materials are guaranteed and better. Since it is a high-quality finish, general combing is used during post-processing.

Combing, semi-combing, and carding are the three methods of carding process:

Combing: It represents high quality and is equivalent to an additional process, which is to draw the carded cotton sliver into a roll, and then further comb it through a combing machine. The purpose is to further remove short lint and impurities in the fiber and make the fiber straight and parallel. The degree is better. In this way, combed strips are made for use in the next process (drawing). The cotton yarn produced in this way has high strength, good evenness and good gloss. Generally used to produce yarns with higher quality requirements or high-count yarns.

Semi-combed: represents medium quality. It is actually between carded and combed. This is generally how it is operated in textile mills. For example, drawing is 6 steps. into one yarn, then among these 6 yarns, there are 3 combed cotton slivers and 3 carded cotton slivers, then the produced yarn is semi-combed yarn. (You can also change the ratio, such as 2 and 4, or 4 and 2)

Card: represents low quality, that is, the cotton roll (blow carding can even be Not rolled) passes through the carding machine to remove impurities and short lint, and is made into sliver for the next process (drawing).