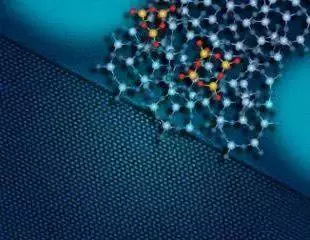

Nanomaterials

Nanometer is a unit of length measurement, 1 nanometer is equal to one billionth of a meter. Nanoparticles generally refer to particles with a particle size between 0.1-100mm. Nanoparticles show special properties in many aspects such as optical properties, catalytic properties, chemical reactivity, magnetism, melting point, vapor pressure, phase transition temperature, superconductivity, etc., making them of great value in the development and production of new functional clothing materials.

At present, nanofunctional materials and nanotechnology have become a hot research topic in various countries around the world. Nanotechnology has penetrated into all fields of human life and production, making Many traditional products have been improved. At present, nanotechnology has been used in the research and development and production of functional clothing materials such as anti-ultraviolet, anti-magnetic radiation, far-infrared, antibacterial and odor-suppressing, anti-aging, water and oil repellent.

1. Nanotechnology Application pathways in textiles

The application of nanotechnology to develop functional textiles is mainly achieved through the following three ways:

(1) Ultra-fine fiber,Use nanotechnology to make fibers reach the nanometer level to meet the needs of special application fields.

(2) Use nanomaterials to modify traditional materials.

For example, solution blending in wet spinning means that after the polymer is dissolved in an appropriate solvent, nanomaterial particles are added Among them, the polymerization reaction is carried out after sufficient stirring and uniformity, and then the spinning process is carried out. In melt spinning, nanoparticles are evenly dispersed in the molten polymer to prepare functional fibers.

(3) Nano-finishing the fiber or fabric to functionalize it.

The main methods of nano-finishing are: adding nanoparticles as solid substances directly into the fabric finishing agent to make the nanoparticles evenly dispersed In the fabric; after uniformly mixing the microemulsion of nanoparticles and the fabric finishing agent, the fabric is passed through the finishing liquid containing nanoparticles; the finishing agent containing nanomaterials is applied to the fabric in the presence of a certain adhesive. On the surface, a functional coating is formed to improve the wearing properties of the fabric.

No matter which of the above methods is used, the characteristics of the original textile or clothing materials can be changed and new functions added. Some newly developed products have already entered the market. It has entered the daily consumption field, such as water-repellent cashmere windbreakers, anti-fouling ties and trousers, antibacterial and anti-inflammatory underwear, UV-blocking jackets, etc.

2. Nanotechnology Functional clothing materials

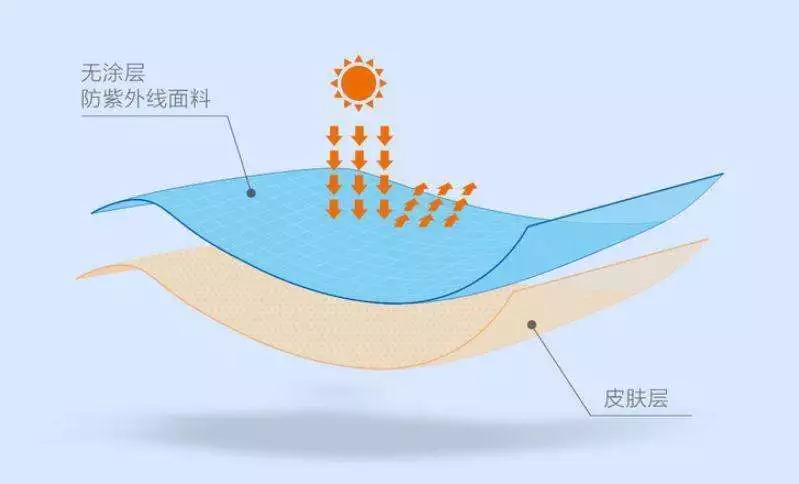

(1) UV protection material

UV protection diagram

The ultraviolet rays from solar energy that are harmful to the human body are mainly in the 300~400mm band. Research shows that nano-TiO₂, ZnO, SiO₂, Al2O3, Fe2O3 and nanomica all have the characteristics of absorbing ultraviolet rays in this band. If a small amount of nanoparticles are added to chemical fibers, ultraviolet absorption will occur, which can effectively protect the human body from ultraviolet damage.

(2) Antistatic material

Flame retardant Antistatic fabric

Chemical fiber clothing and carpets produce a discharge effect due to electrostatic friction and are easy to absorb dust, causing a lot of inconvenience to users. Nanoparticles are a solution The electrostatic problem of chemical fiber products provides a new way to add a small amount of nanoparticles to chemical fiber products, such as 0.1%-0.5% of nano-TiO₂, CR₂O3, ZnO, Fe2O3 and other semiconductor powders into the resin. It will produce good electrostatic shielding performance and greatly reduce electrostatic effects.

(3) Anti-electromagnetic radiation materials

Radiation-proof fabric

The popularity of electronic products has caused electromagnetic radiation to pose a huge threat to human health. Some nanoparticles such as nano-iron oxide, nano-nickel oxide, etc. It can strongly absorb electromagnetic radiation, thereby protecting the human body.

(4) Far-infrared materials

Far-infrared functional fabric

The infrared rays released by the human body are roughly in the mid-infrared band of 4 to 16. On the battlefield, if the infrared rays of this band are not used properly, If shielded, it will be easily discovered by very sensitive mid-infrared detectors. Especially at night, human safety will be threatened. Therefore, it is necessary to develop clothes that can shield the infrared rays of the human body.

Certain nanoparticles such as nano-AI2O3, TiO₂, SiO₂ and Fe2O3 composite powder combined with polymer fibers have strong absorption in the mid-infrared band performance. Another important characteristic is that some nanoparticles, such as nanometer zirconia, can effectively absorb external energy and radiate far-infrared rays that are the same as the human body’s infrared rays. This far-infrared ray acts on the human body, causing resonance activation of human cells, and has the functions of insulation and heat preservation. Antibacterial, promote blood circulation, enhance immunity and other health care functions.

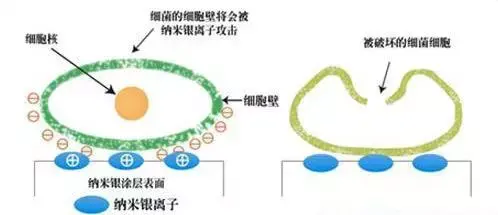

(5) Antibacterial and deodorizing materials

Nano antibacterial principle

Some metal particles such as silver, copper, iron, etc. can release trace amounts of metal ions through them, which interact with negatively charged bacteria The combination of body proteins causes bacteria to deform or precipitate, thereby achieving bactericidal effect. Nano zinc oxide, copper oxide, etc. not only have good antibacterial and deodorizing functions, but also have good ultraviolet shielding effects.

(6) Anti-aging materials

Some Chemical fibers are not resistant to sunlight because organic polymer materials will degrade their molecular chains under ultraviolet irradiation and produce a large amount of free radicals, which will affect the color and strength of fibers and textiles. Nano titanium dioxide particles are a stable The ultraviolet absorber is evenly dispersed in the polymer material, and its absorption of ultraviolet rays can be used to prevent the degradation of the molecular chain, thereby achieving the effect of sun protection and aging resistance.

(7) Water and oil repellent materials

Water and oil repellent

Perform some special processing on the surface of the material to give the material a special function. Textile materials (cotton, linen, silk, wool, velvet, blended fabrics, chemical fibers, etc.) treated with this technology are not only waterproof and oil-proof, but also resistant to ink, juice, etc. Clothing made from this fiber can be rinsed with just water, eliminating the need to use traditional detergents.

�, also has good UV shielding effect.

(6) Anti-aging materials

Some Chemical fibers are not resistant to sunlight because organic polymer materials will degrade their molecular chains under ultraviolet irradiation and produce a large amount of free radicals, which will affect the color and strength of fibers and textiles. Nano titanium dioxide particles are a stable The ultraviolet absorber is evenly dispersed in the polymer material, and its absorption of ultraviolet rays can be used to prevent the degradation of the molecular chain, thereby achieving the effect of sun protection and aging resistance.

(7) Water and oil repellent materials

Water and oil repellent

Perform some special processing on the surface of the material to give the material a special function. Textile materials (cotton, linen, silk, wool, velvet, blended fabrics, chemical fibers, etc.) treated with this technology are not only waterproof and oil-proof, but also resistant to ink, juice, etc. Clothing made from this fiber can be rinsed with just water, eliminating the need to use traditional detergents.