Functional fabrics: (4) Flame-retardant fabrics

In recent years, fires caused by textiles have been increasing in countries around the world. Over the past few decades, the average number of fires that have occurred in our country every year has been 30,000 to 40,000, with 2000 to 3000 deaths, and fire losses of 200 to 300 million yuan.

With the development of the economy and the improvement of the national legal system, the promotion and application of flame-retardant textiles has attracted the attention of the whole society. There is a lot of development and research on flame-retardant fabrics abroad. Some industrially developed countries formulated flame-retardant regulations for textiles as early as the mid-1970s. In recent years, the requirements have become higher and higher, and the regulations have become more and more detailed. The Fire Protection Law of the People’s Republic of China, which came into effect on September 1, 1998, has promoted the development of flame-retardant textile technology in my country. In recent years, my country’s research and development on flame-retardant textiles has gradually increased and considerable progress has been made. With the acceleration of urban modernization, the development of tourism and transportation industries, and the increase in demand for export textiles, there is a huge potential market for flame-retardant textiles. According to the survey, the consumption of flame retardant products is mainly distributed in the steel casting industry, fire service industry, chemical manufacturing industry, etc. Public service units mainly include: hospitals, military, and forest fire-fighting service teams. In addition to clothing, flame-retardant textiles for cars, trains, and airplanes, as well as seat covers, curtains, and decorative fabrics for hotels, theaters, auditoriums, and other places also have endless potential.

There are two main ways to achieve flame retardant functionality in textiles:

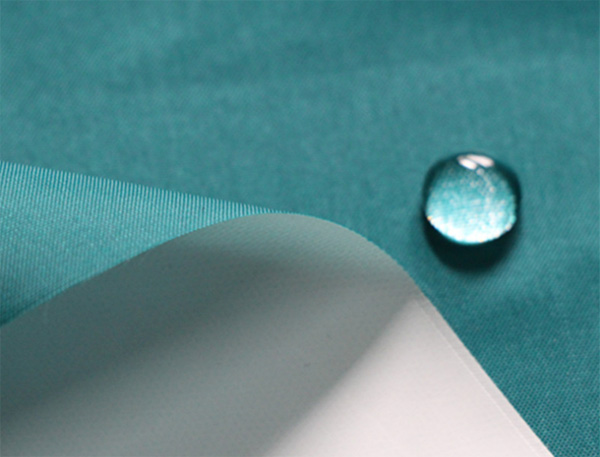

1. Apply the flame retardant layer on the surface of the fabric or penetrate into the fabric using post-finishing methods.

Currently, the internationally popular flame retardant technologies include Proban and CP flame retardant.

Proban is a water-soluble flame retardant that easily penetrates into the fiber, making it flame retardant. It is a finishing flame retardant for cotton fiber and its blended fabrics. Its main feature is that after using this flame retardant to produce and finish, permanent cross-linking is formed inside the fabric, thus making it flame retardant. performance and maintain the original performance of the fabric.

CP flame retardant fabric is a flame retardant fabric produced using imported technology and imported environmentally friendly flame retardants. It is superior to polybenzene flame retardant fabric. The most important thing is that the formaldehyde content achieved after washing and formaldehyde capture treatment can fully meet foreign standards. And the formaldehyde content will not rebound over time. However, the fabric strength loss caused by CP flame-retardant processing is slightly greater than that of proben flame-retardant fabrics, and the price is higher.

2. The flame retardant with flame retardant function is added to the fiber through polymer polymerization, blending, copolymerization, composite spinning, joint extrusion modification and other technologies to make the fiber flame retardant, that is, flame retardant fiber.

The flame-retardant fibers currently used in domestic and foreign markets mainly include: aramid, flame-retardant acrylic, flame-retardant viscose, flame-retardant polyester, flame-retardant vinylon, etc. In addition to excellent flame retardant properties, the flame retardant fabrics produced using these fibers are most famous for their strong washability. Since they are flame retardant fibers themselves, ordinary industrial washing will not affect their flame retardancy. performance, it is called a permanent flame retardant fabric.

Flame retardant products produced using flame retardant fibers have the following properties:

1. Excellent permanent flame retardant and fire retardant properties. Washing and friction will not affect the flame retardant properties.

2. Good safety. When the fiber encounters fire, it releases low smoke and does not release poisonous gas.

3. Using conventional fiber as the carrier, it does not produce harmful elements and meets environmental protection requirements.

4. Good thermal insulation, providing all-round thermal protection.

5. The fabric has the moisture absorption and release properties of conventional fibers, and has the characteristics of soft feel, comfort, breathability, and warmth.

6. Post-finishing flame retardant is mainly used for cotton or low-proportion chemical fiber fabrics, and flame-retardant fibers use various chemical fibers as carriers to give full play to the excellent properties of various chemical fibers.

Flame retardant fabrics have a wide range of applications and can be used to make protective clothing and special functional clothing. They are widely used in the military, firefighting, petroleum, electric power, natural gas, metallurgy, machinery, mining, chemical industry, aviation, shipping and other industries; to make general clothing, Especially children’s clothing, pajamas, etc.; making home and hotel decoration supplies, such as carpets, curtains, bedding, etc.; industrial machine covers, tents, etc.