Basic knowledge of cotton and linen fabrics

Today the editor will take you to understand the characteristics of cotton and linen fabrics, common quality problems and their causes, What are the prevention methods and repair methods?

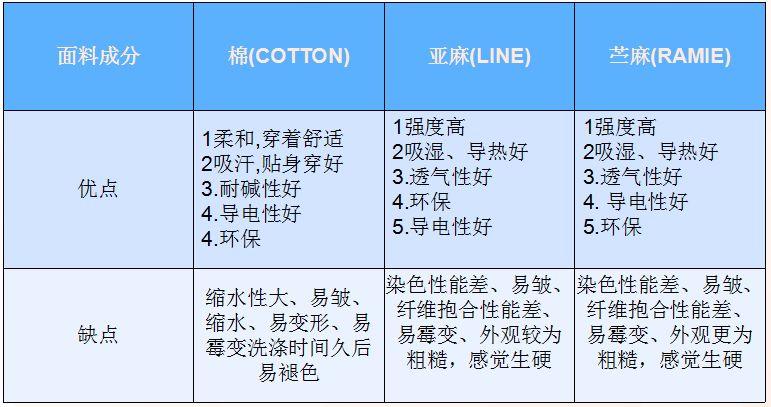

The advantages and disadvantages of cotton and linen fabrics

The difference between linen and ramie

First, appearance, ramie products have obvious wrinkles and sharp edges, while linen products have larger wrinkles, natural, and will Slowly spread;

The second is the cloth surface. The structure of ramie is very loose, and the gaps between the warp and weft lines of the fabric are large. The cloth surface of linen has a very full structure and special drape. Good;

Third, when exposed to water, ramie products harden, while linen products are very soft.

Common quality problem categories of cotton and linen products

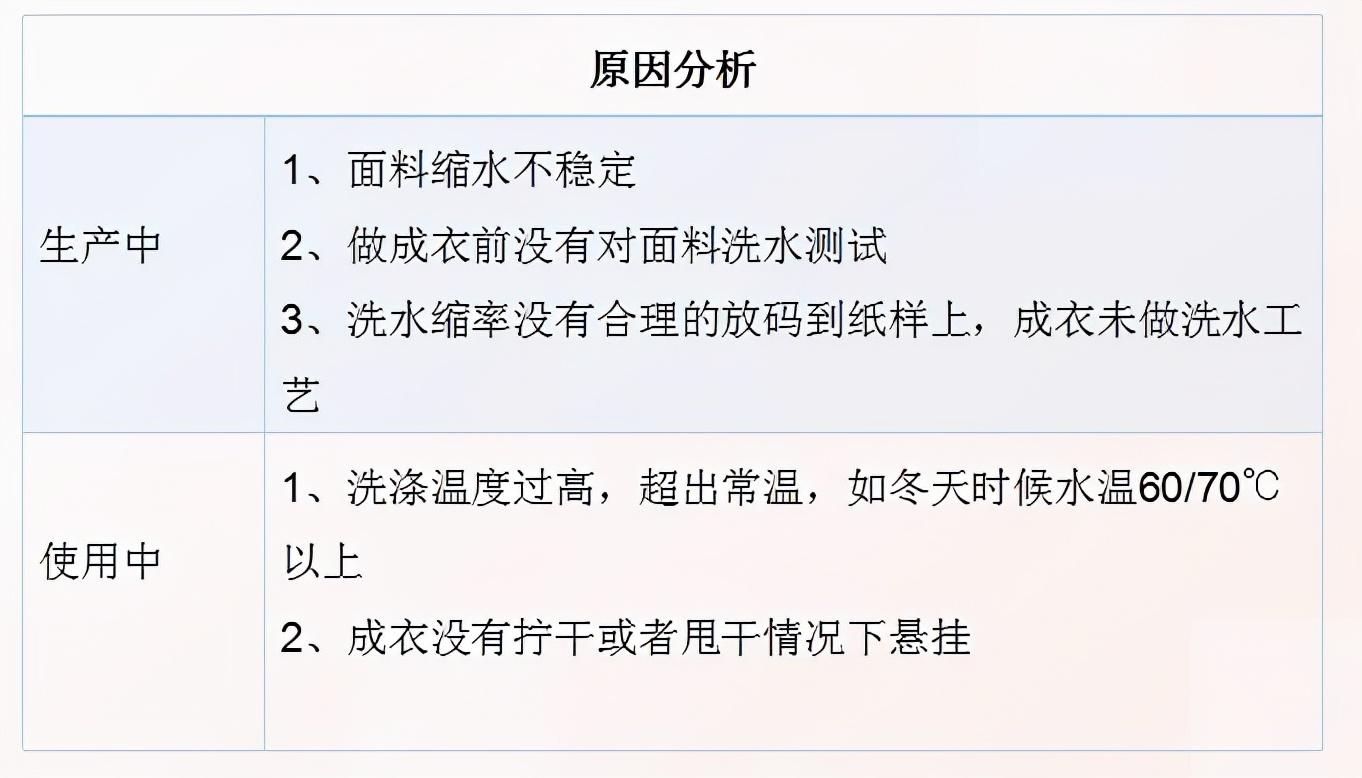

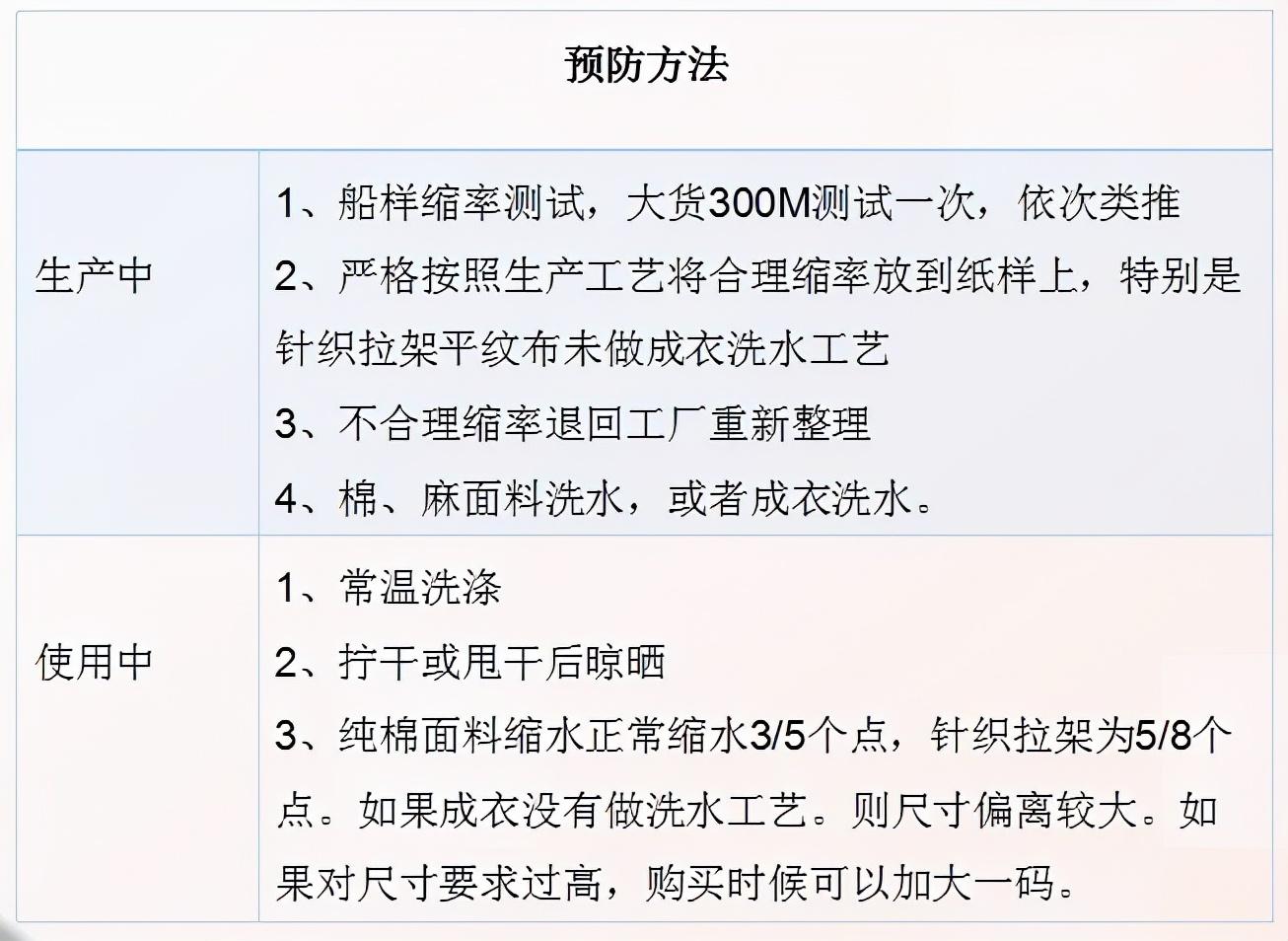

1. Fabric shrinkage

2. Fabric fading

(1) Fabrics fade and match colors evenly

Note: Clothes fade evenly during normal washing Faded, no stains or flowers

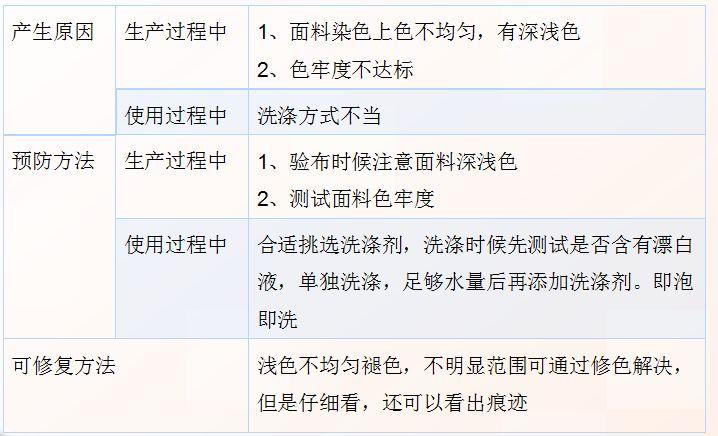

(2) Fabric fading (uneven fading)

Explanation: Clothes fade unevenly during normal washing, with color spots and flowers

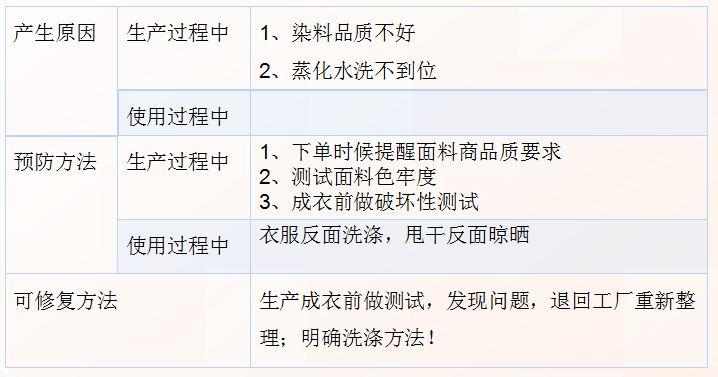

(3) Fabric fading (printing and dyeing fading)

Explanation: The color fastness of fabric printing is not up to standard, causing fading

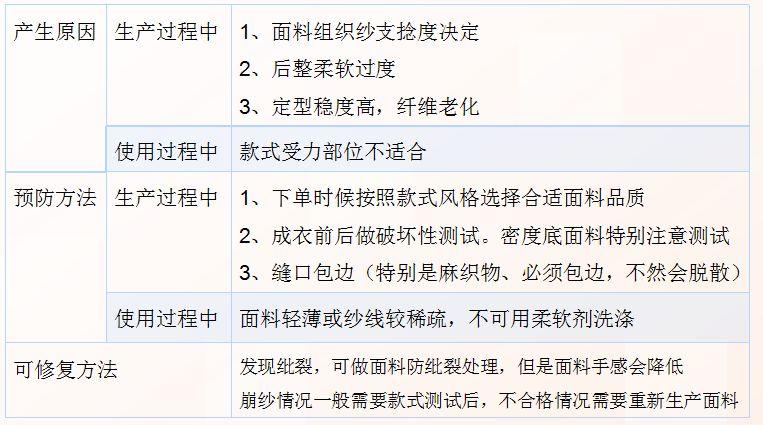

3. Fabric rips and yarn collapse

Explanation: Clothing rips refer to clothing that is damaged during use During the process, due to the stretching effect of external force, the fabric yarns will slip in the warp or weft direction at the seams, causing the seams to come apart. Yarn collapse is when the yarn breaks under a certain force.

4. The fabric turns yellow and the gloss is reduced

Explanation: The color of the fabric is different from the color during washing and storage. The original color comparison showed that the color was yellow and not as fresh as before

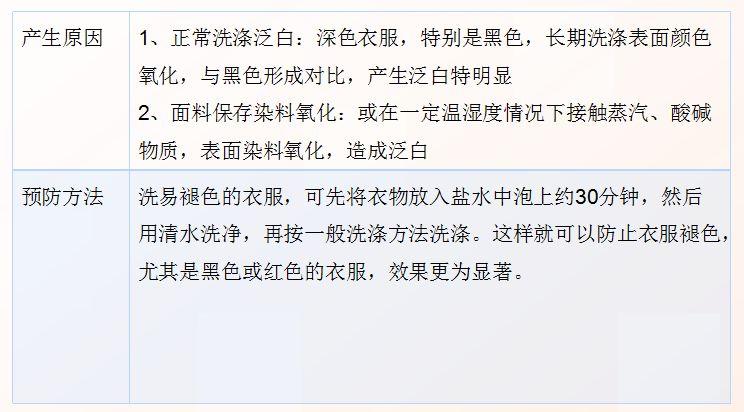

5. The fabric turns white

Explanation: The color of the fabric changes from the original color during washing and storage. In contrast, the color is whitish, and the surface looks like a layer of fog

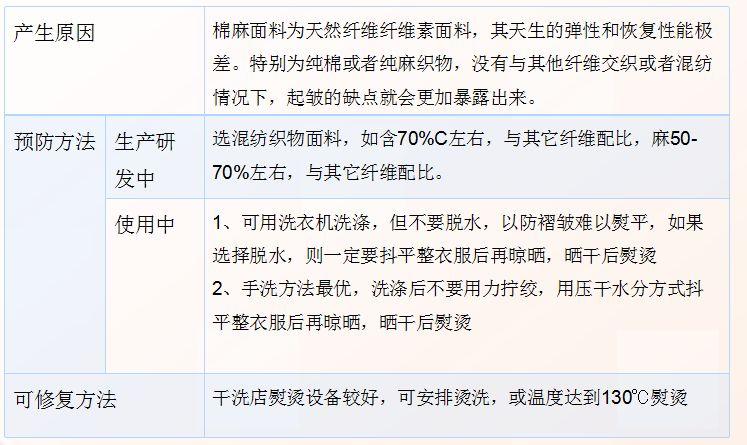

6. Fabric wrinkles

Instructions : Clothes are uneven after washing or wearing.

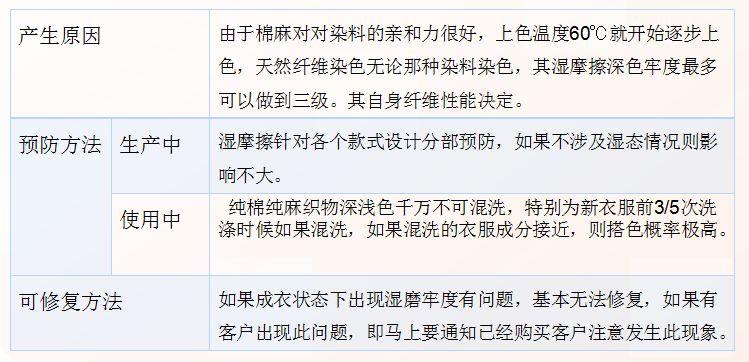

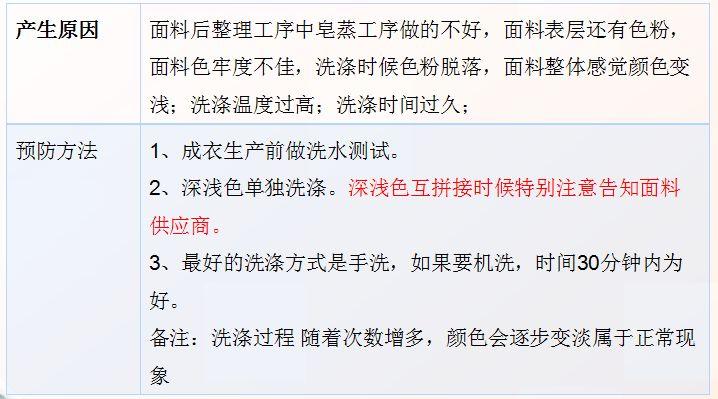

7. Low color fastness to wet rubbing

Explanation: The color fastness of the fabric when rubbed with other fabrics in a wet state. For example, if you wear cotton or linen clothes, your clothes will get wet when it rains, and the color will get mixed into your coat or bag.