Before introducing the T-shirt technology

Let’s first understand the history of T-shirts

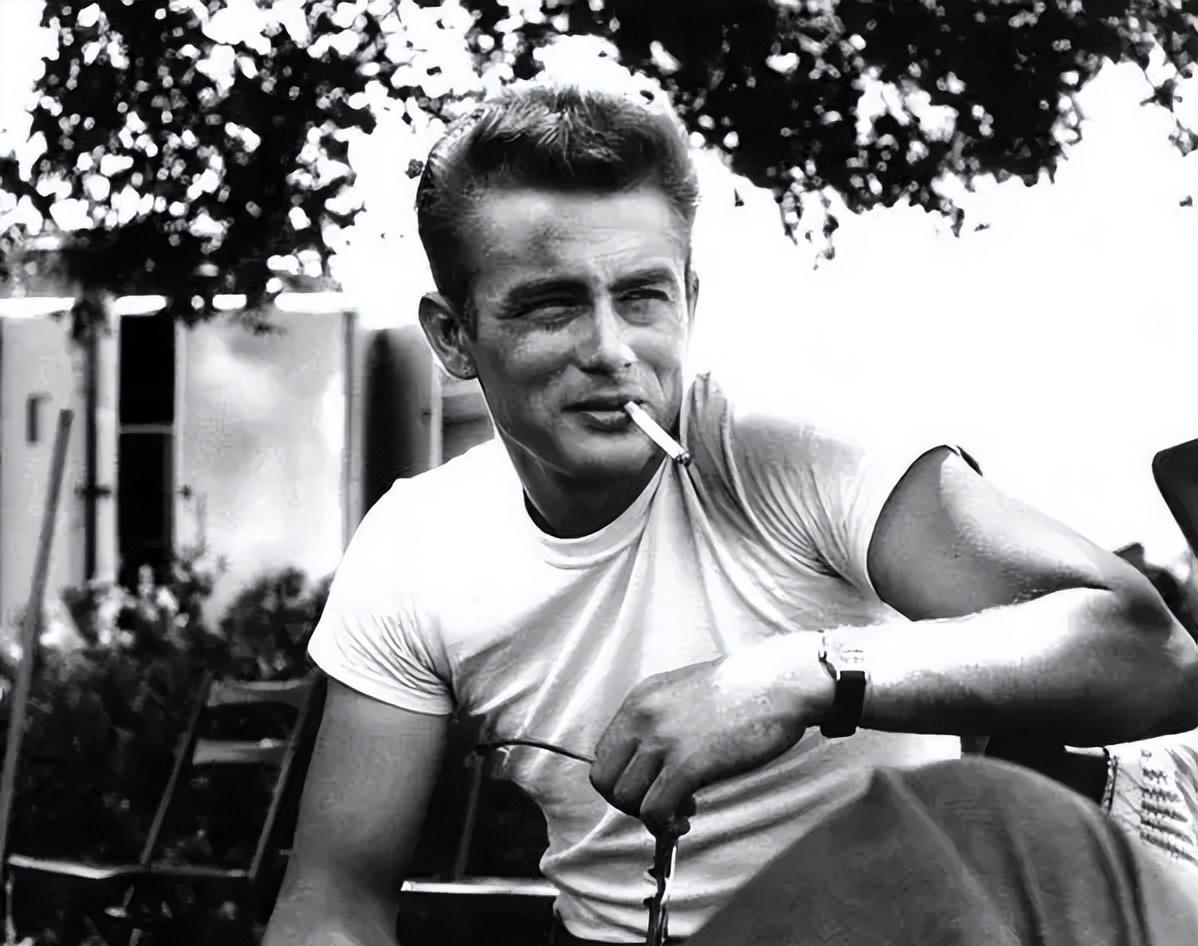

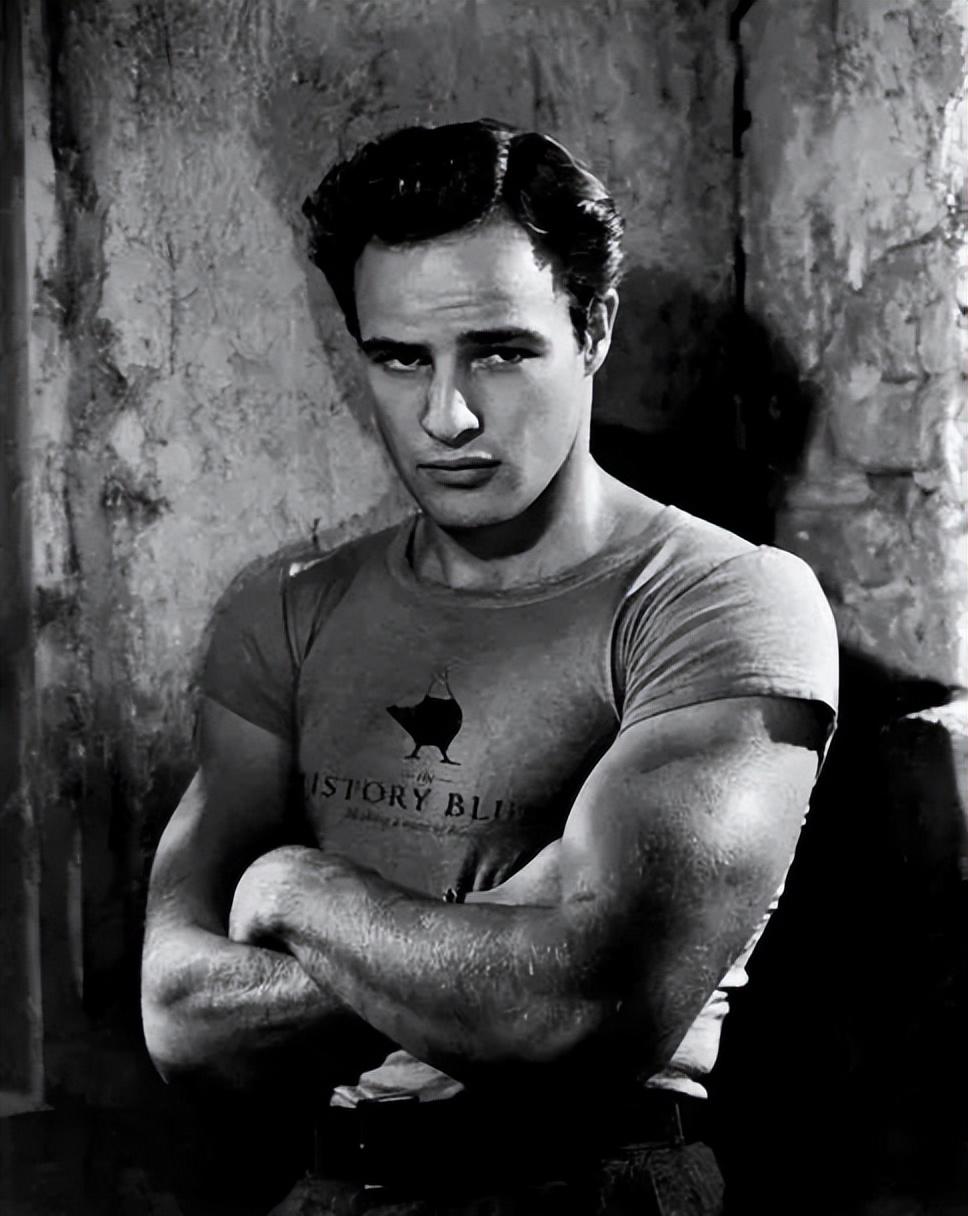

T-shirts were originally used as underwear, and later became popular among sailors, soldiers and workers. After World War II, with the help of some celebrities, T-shirts were accepted by more people and became a single item that could be worn outside.

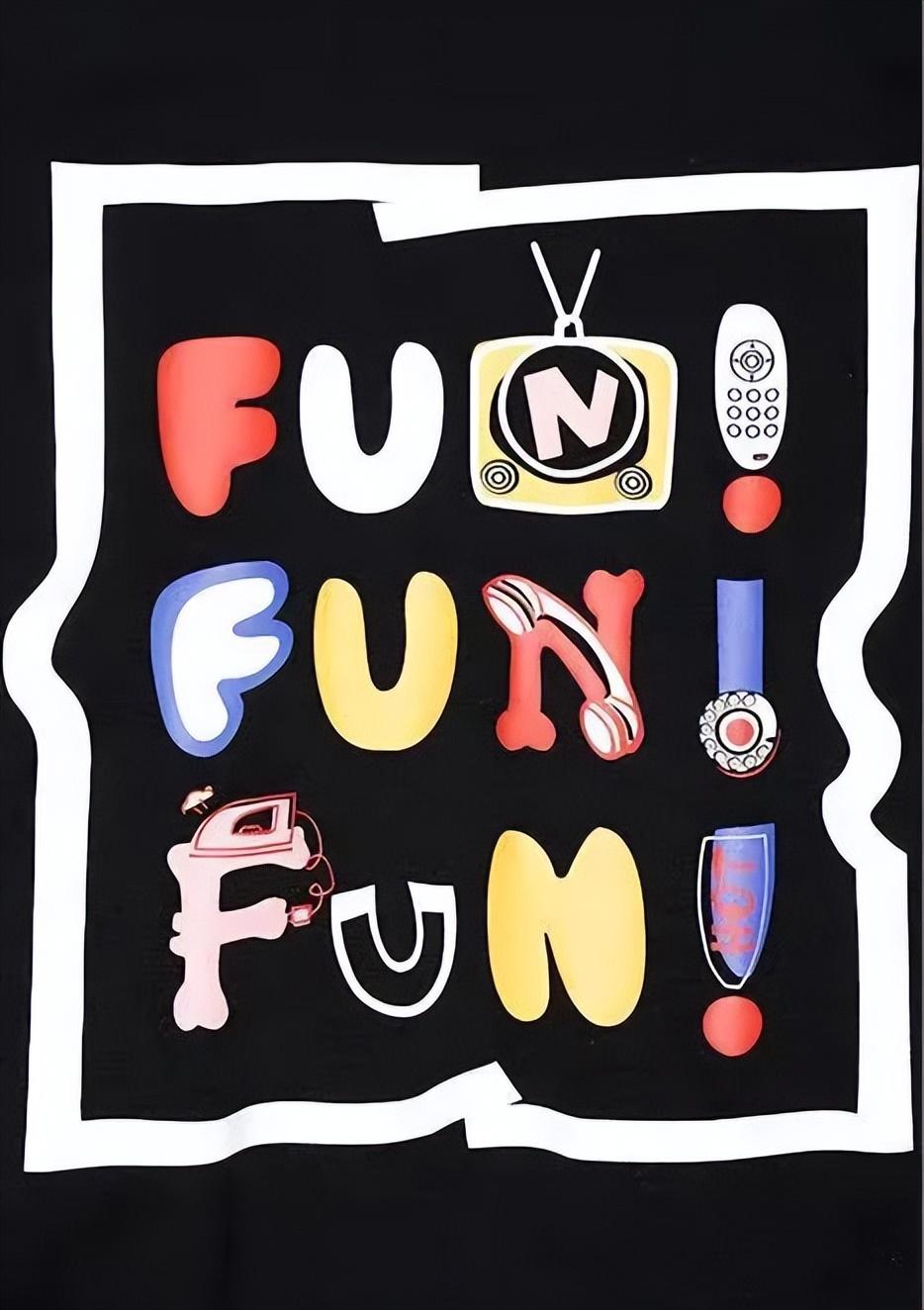

In the 1960s, catching up with the rise of rock music and the hippie movement, T-shirts became a means of self-expression and promotion. The media displayed a wide range of patterns, including large characters, slogans, pictures and even photos, so the T-shirt printing process for self-expression was born.

T-shirt printing process types

1. Part.1 Digital Direct Injection

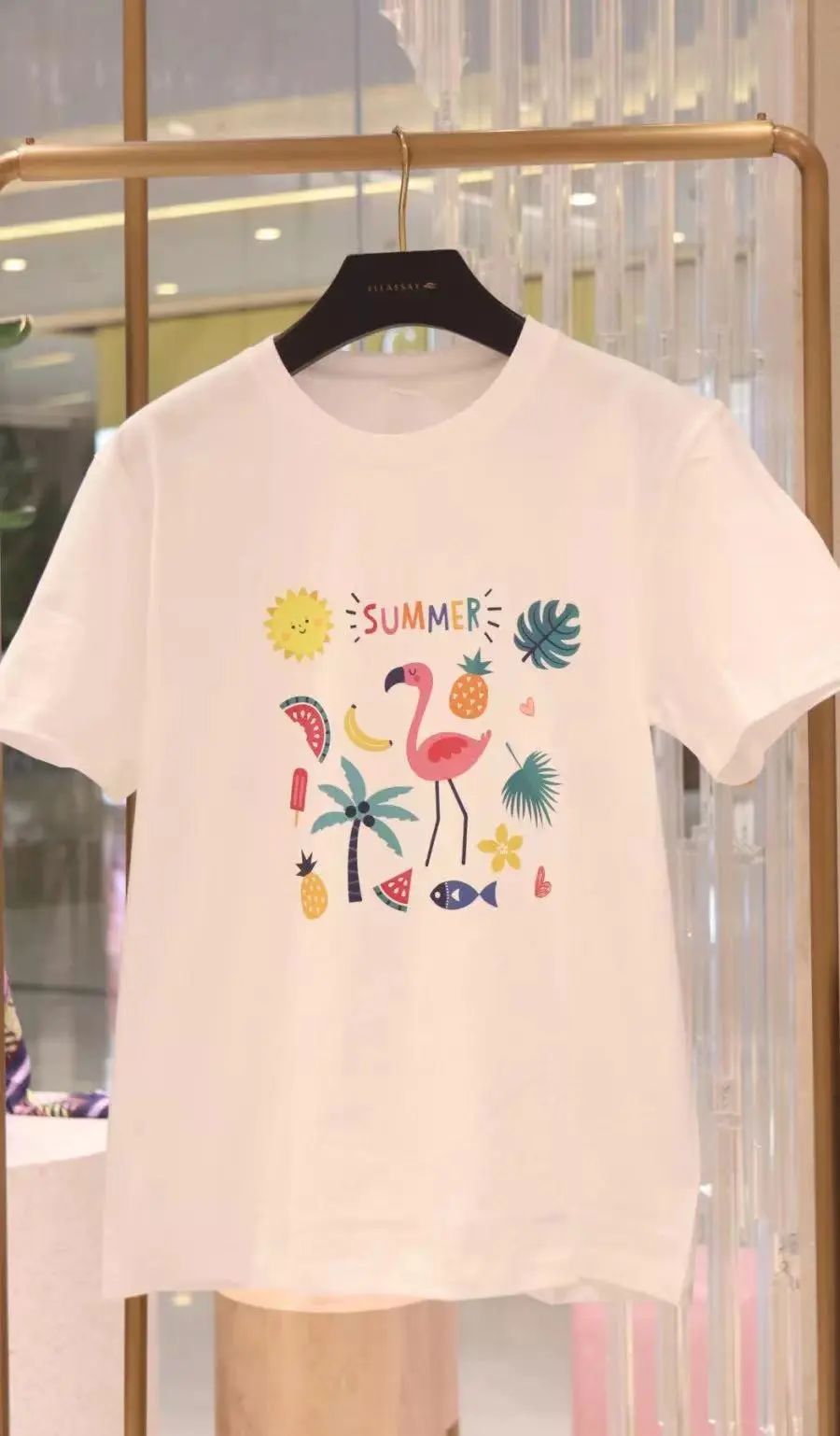

Digital Direct Injection , refers to using a digital printer to directly print the required patterns on various materials. The working principle is similar to that of a printer. It is suitable for light-colored fabrics, and dark-colored fabrics can also be spray-painted after being primed with a special slurry.

Advantages: Can be ordered in one piece, feels good, and is more suitable for complex patterns and colors.

Disadvantages: Not suitable for printing on dark T-shirts. Generally, the best effect is printed on white cotton bottom shirts.

2. Part.2 Screen printing

Through silk screen printing The unique technology of screen plate making, combined with the photosensitive exposure characteristics of photosensitive adhesive, makes the mesh holes of the pattern part to be printed in an open state, while the non-pattern part is in a closed state. During printing, due to the scraping effect of the screen printing squeegee, the printing paint paste can smoothly penetrate into the surface of the fabric through the screen mesh, allowing the printing material to be printed on the clothes, thus completing the printing process.

Advantages: The plate making cost is relatively low, the printing process is simple and convenient, and it is suitable for some garment printing processes with tight time and small quantities. The order can further demonstrate the advantage of her speed of delivery.

Disadvantages:

①The printing speed is much lower than other printing methods

②The printing lines are thick and cannot print very fine patterns

③The printing level is poor, the highlight part is not easy to print, and the dark part is easy to paste

3. Part.3 Thermal transfer printing

Thermal transfer printing can be said to be the A supplement to screen printing, because many images that are too complex cannot be completed by screen printing, there is thermal transfer printing. Simply put, heat transfer printing is to press special paper with printed images onto clothes through a heat transfer machine.

Advantages: The printing pattern is vivid in color, fast and convenient.

Disadvantages: Some light-colored patterns are not clear enough, and the areas where the pictures are printed are not breathable.

BYB printing technology is rich, including ink printing, digital direct printing, offset printing, embroidery, heat transfer printing, hot stamping and silver foil, etc. Visible exquisite craftsmanship, exclusive customization for your self-expression, and protection of your T-shirt elements.