The hot summer is about to enter. If you want to choose the most active item in summer, it must be a T-shirt.

Dancing T-shirts

T-shirts are very common, there are no technical barriers, and there are many companies that make them. The price ranges from 4.9 yuan a piece to several thousand yuan a piece. , it can be so low that you find it incredible, or it can be so high that you find it incredible.

Are there any big differences between them? How to see it?

The production of all products starts from raw materials.

Almost all fiber materials can be used to weave T-shirts, including cotton, wool, silk, linen, viscose, mercerized cotton, Tencel, polyester, nylon, etc. Of course spandex fiber is essential in T-shirts, it can provide good elasticity.

Among these materials, polyester and nylon are relatively cheap, silk is more expensive, and cotton is the most common.

If the content of polyester or nylon in the raw material of a T-shirt exceeds 50%, unless the special features of polyester or nylon can be explained, if the price exceeds 100 yuan, it is definitely unreasonable.

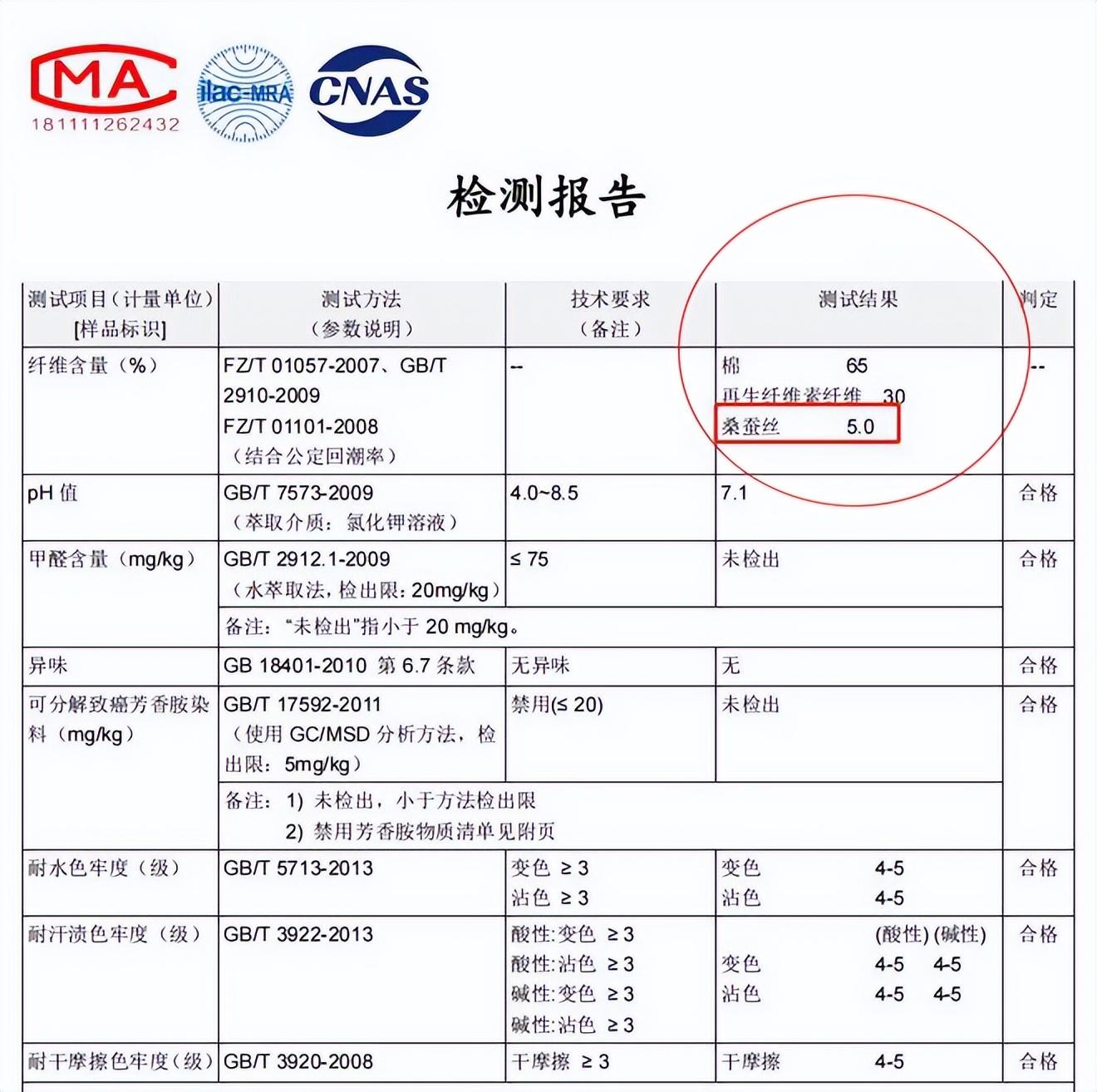

Test report

“Xinjiang cotton output in 2020/2021 was 5.2 million tons, accounting for about 87% of domestic production and about 67% of domestic consumption. %.”

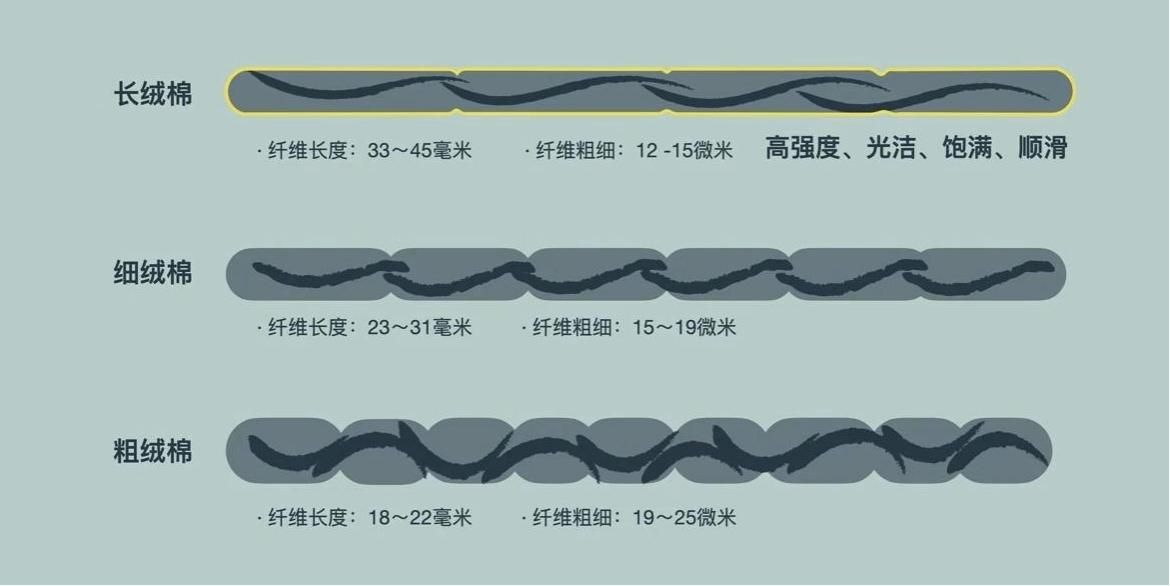

Almost all domestic T-shirts are made of Xinjiang cotton. Xinjiang cotton also has advantages and disadvantages, including not only long-staple cotton, but also upland cotton (fine-staple cotton). Xinjiang long-staple cotton is the best. For the same count (an indicator of fineness, the higher the count, the finer the yarn), the price of long-staple cotton yarn is 1.3 times that of fine-staple cotton.

On some platforms, merchants emphasize that the raw material of T-shirts is Xinjiang cotton. This is actually a very common gimmick, and we do not need to add points for this.

The current price of 21 counts of 1-strand high-quality cotton ring-spun yarn (long-staple cotton) is about 29,000 yuan/ton, and 32-count cotton ring-spun yarn (long-staple cotton) The price of one share of high-quality products is about 31,000 yuan/ton.

Three kinds of cotton

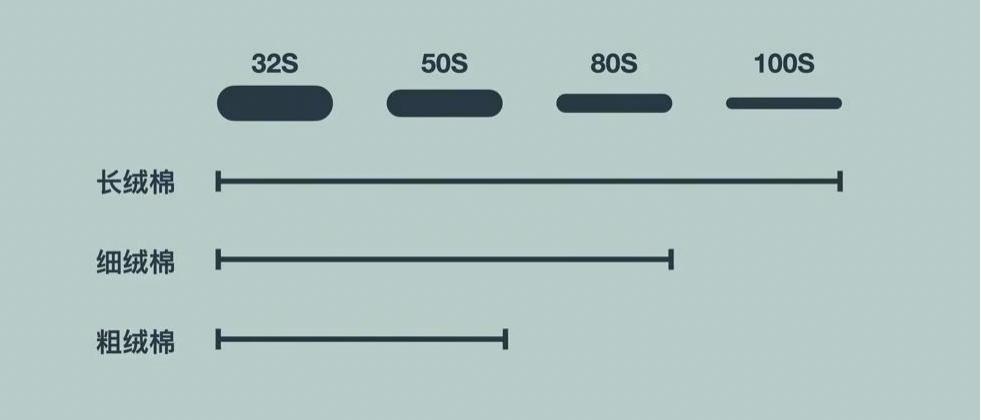

Count is an important reason for the large price difference of fabrics.

Count

The count of ordinary T-shirts is concentrated between 20 counts/double ply and 32 counts/double ply, which is a low yarn count , the intuitive feeling is not that big.

High-end T-shirts may use 60-count/double-strand to 80-count/double-strand. High-count fabrics have a strong softness and the gloss of the fabric will also be improved. .

Some high-end T-shirts also use low-count yarn to show the wideness of the T-shirt.

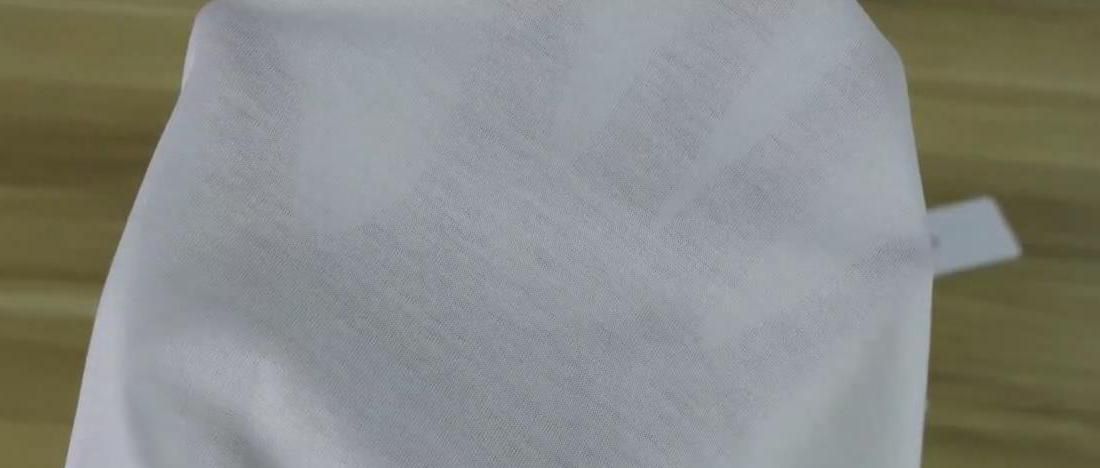

T-shirts use less cotton yarn with a count higher than 80. This is because the fabric is too thin and has good skin-friendliness. The phenomenon shown is the light transmittance of the T-shirt. If it is higher, it will show spots, and it will be close to the skin, which will reduce the comfort.

Choosing T-shirts made of high-count fabrics (more than 60 count) means choosing a higher price, which generally costs more than 300 yuan. The surface of this kind of T-shirt will have an elegant glossy feel, which is different from the matte feel of T-shirts made of low-count fabrics. It also needs to be carefully taken care of when used. It is easier to deform. It cannot be washed and dried in a machine. It can easily become high-end. rag.

If you wear it for daily commuting, it is recommended to choose good quality, thicker and low-count fabrics. 20 counts/double strands are easier to take care of and cost 50-100 yuan. .

The 80 count is a bit see-through and will show some spots

The gram weight (weight per square meter) can better reflect the difference in fabrics and reflect the characteristics of the fabrics, especially thickness. The weight of general T-shirt fabric is 170-220g. The larger the gram weight, the thicker it is, and the smaller the gram weight, the thinner it is.

The weight of the fabric depends on the yarn count and the density (tightness) of the fabric. High-density fabrics generally have better stability, good shape retention, and thick hand feel, but will not affect the drape performance of the fabric.

If a piece of fabric feels thick and stiff, it means that the drape performance is not good and it is not soft enough. The quality of the raw material is relatively poor. The reason may be that the single fiber length is longer. For short cotton, it is also possible that the fabric was not treated well enough during the finishing process. For example, the chemical reagents were not cleaned, or the high temperature setting temperature destroyed the original elasticity of the fabric fiber.

After all, softness is an important indicator of comfort.

Of course, there are many factors that affect the softness of fabrics. Poorer fabrics can become very soft if softened.

It is also very common for T-shirts to use brushed cotton fabrics.

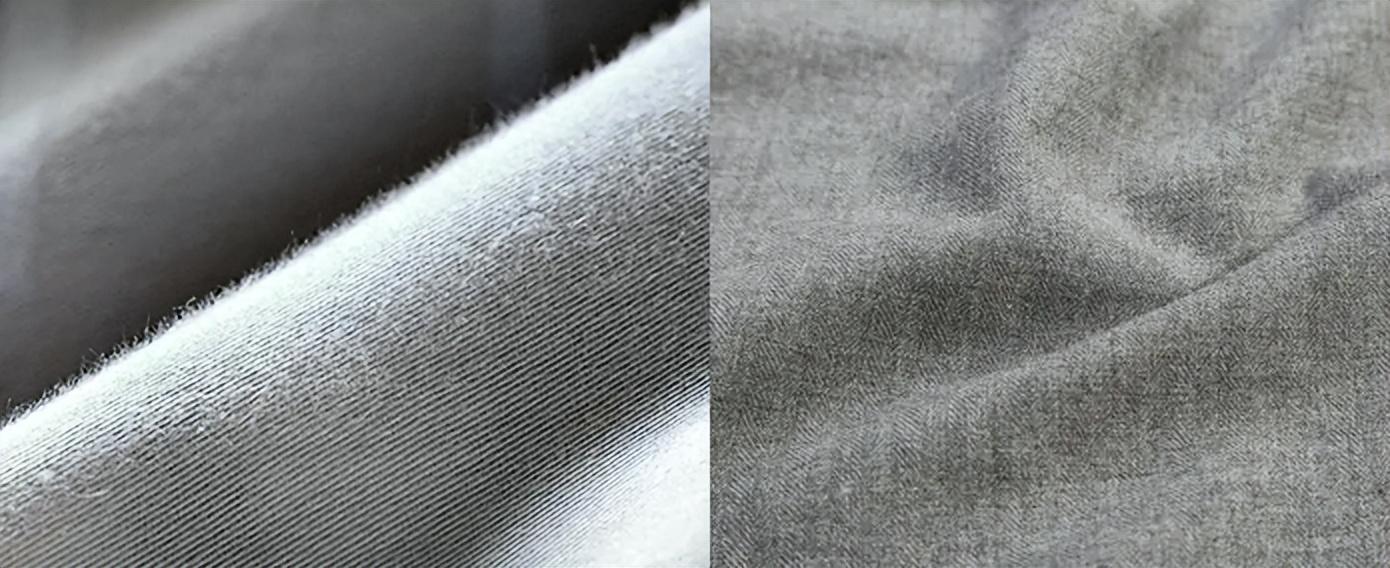

Sanded fabric

The friction between the sanding machine and the emery leather is used to pull the fibers on the surface of the fabric.Pulling it up, this treatment will damage the strength of the fabric, but it will also make the fabric feel softer, richer in texture, and improve the drape performance. This should be a positive treatment. After all, adding a finishing process also increases the cost. .

If you like a smooth and cool feeling, don’t choose T-shirts made of brushed fabrics. If you like softness and texture, choose brushed fabrics.

Cotton is the most commonly used T-shirt raw material, but it also has shortcomings, such as easy wrinkles, shrinkage, and poor gloss.

In order to improve these shortcomings, special cotton fabrics are available on the market.

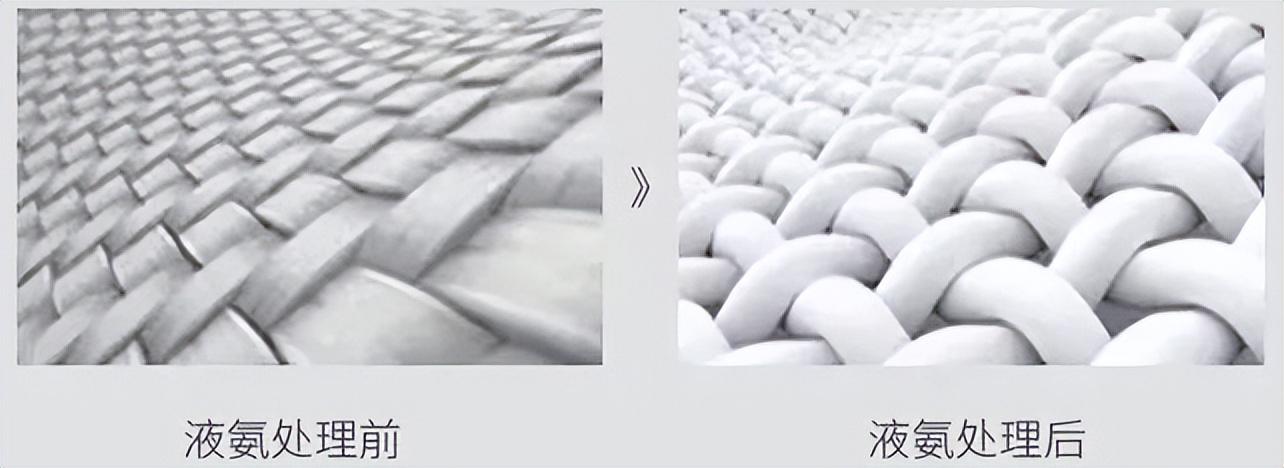

Pure cotton T-shirts that have been mercerized (liquid ammonia process is most commonly used) have fundamentally changed the cross-sectional shape of the fiber, and the waist-circular cross-section has become round. The shape and gloss have been greatly improved, and the wrinkle and shrinkage properties have also been improved.

Before and after liquid nitrogen treatment

Mercerized T-shirt

Can also improve the wrinkle and shrinkage of cotton T-shirts There is anti-wrinkle finishing. Anti-wrinkle finishing often uses chemical reagents containing aldehydes. This is a relatively polluting and unhealthy process. It will also make the plastic feel of cotton T-shirts sharply increase, so it is generally not recommended.

Anti-wrinkle

Three-proof T-shirts and cool-feeling T-shirts are the marketing trends in recent years Hotspot, there is nothing new in technology. In the future, the editor will do a special issue of related technical analysis.

Three-proof finishing

Mercerized finishing, anti-wrinkle finishing, three-proof finishing or cool finishing will not increase the cost of T-shirt fabrics. In effect, the functions of three-proof finishing and cooling finishing often disappear after three or five washes. It is unreasonable to significantly increase the product price based on these concepts.

“Noble clothing and supplies should be made of pure natural materials” and do not require excessive modification.

To judge the quality of T-shirts, fabric is the basis and workmanship is the key. The relevant content will be updated soon.