When we buy bedding products, in addition to price and style, we focus on the fabric composition. When given a choice, most people would prefer natural fiber fabrics such as cotton, linen, wool, and silk, believing that natural ingredients are safe and highly comfortable.

Correspondingly, when it comes to chemical fiber fabrics, everyone will avoid them, thinking that they are of poor quality, prone to static electricity, stuffy and not breathable, and not skin-friendly and comfortable enough.

The reason why people have prejudices against chemical fiber fabrics mainly stems from the fact that in the 1970s and 1980s, Doliang (that is, polyester) left people with It is caused by the long-term impression of “non-hygroscopic and sticky”. So when it comes to chemical fiber, people will naturally equate it with polyester (polyester fiber).

But since the emergence of the first chemical fiber, there have been hundreds of types of chemical fibers used for textiles, not just polyester. Today, as technology becomes more advanced, some chemical fibers have improved a lot in terms of performance and comfort, and are even better than natural fibers in some aspects. These preconceived notions should also be changed:

Chemical fibers treated with specific processes are actually no worse than natural fibers!

▲The moisture absorption and breathability of technically treated fabrics will be greatly improved.

Traditional chemical fiber fabrics are prone to friction and electrification and have poor skin-friendliness, mainly because the fabrics have poor hygroscopicity (low moisture regain) and are too dry. New chemical fiber fabrics have improved the moisture regain of the fiber by improving raw materials and manufacturing processes, overcoming the shortcomings of traditional chemical fiber fabrics such as static electricity and poor skin affinity, making them more skin-friendly.

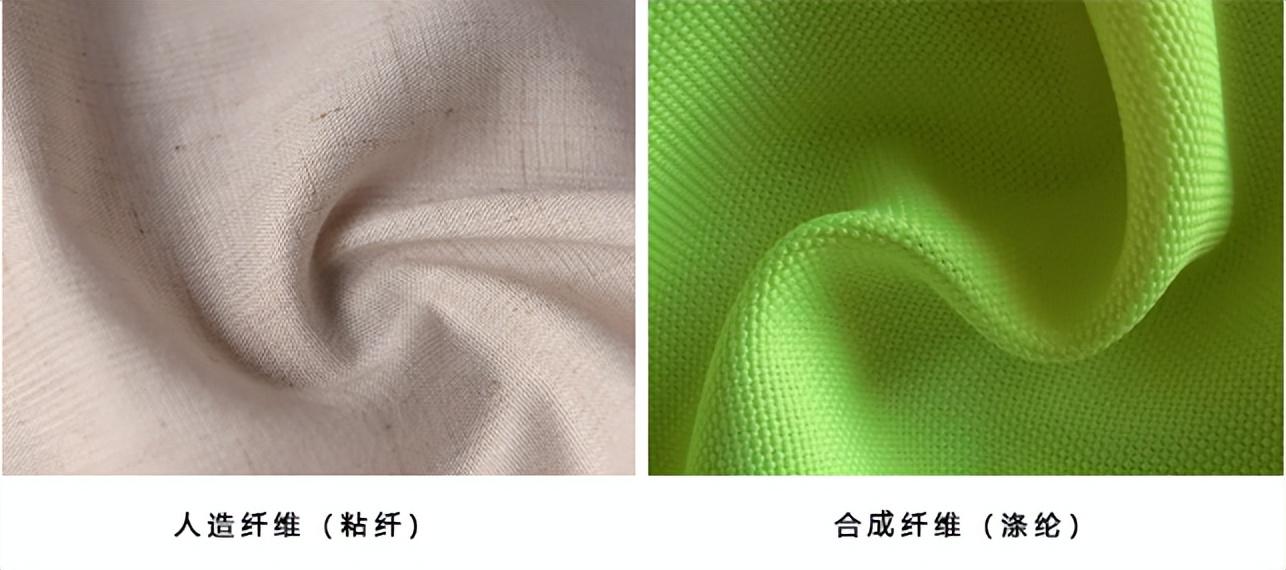

The so-called improvement of raw materials means the improvement of polymer compounds into cellulose extracted from plants or proteins. Therefore, based on the raw materials, chemical fiber fabrics can be divided into two categories: man-made fibers and synthetic fibers.

1. Man-made fiber

Man-made fiber, also known as regenerated cellulose fiber, is extracted from plants Or cellulose in protein, which is processed by certain chemical processes and then spun into silk. Such as viscose fiber, modal fiber, bamboo fiber, cupro fiber, as well as lyocell fiber, acetate fiber, which have been in the limelight in recent years, are all man-made fibers.

Man-made fibers generally have the characteristics of good hygroscopicity, soft and comfortable feel, good drape and no wrinkle resistance.

|

Natural fiber |

Official regain rate |

Chemical fiber |

Official moisture regain rate |

|

Cotton |

6%-9% |

Viscose |

12-13% |

|

hemp |

12%-14% |

Modal fiber |

11%-13% |

|

Silk |

8%-11% |

Lyocell fiber |

8%-14% |

|

hair |

15%-19% |

Bamboo fiber |

12%-13% |

|

acetate |

4%-7% |

||

|

Cupramine fiber |

11%-14% |

▲This table shows the air temperature is 20℃ , the official moisture regain of various fibers at a relative humidity of 65%.

We can also see from the table that the moisture regain of most regenerated cellulose is not higher than that of everyone’s favorite It is worse than pure cotton, even better than pure cotton and silk.

For example, lyocell fiber and acetate fiber, which have become popular in the past two years, have no feel, gloss and drape. Not inferior to silk fabrics woven from silk. Therefore, the price is not cheap.

Lyocell fiber bedding

2. Synthetic fiber

Synthetic fibers are made of polymer compounds. Common ones include polyester fiber, spandex, acrylic fiber, acrylic fiber, etc. Most of the fibers used in bedding are polyester, that is, polyester fiber.

Synthetic fibers have the advantages of being strong and durable, easy to wash and dry quickly, and not easy to breed bacteria and insects.

|

Synthetic fiber |

Official regain rate |

Synthetic fiber |

Official moisture regain rate |

|

Polyester |

0.4%-5% |

Spandex |

0.4%-1.3% |

|

Nylon 6 |

3.5%-5% |

Acrylic |

1.2%-2% |

|

Polyamide 66 |

4.2%-4.5% |

Vilon |

4.5%-5% |

▲This table shows the public moisture regain of synthetic fibers when the air temperature is 20°C and the relative humidity is 65%.

Comparing the two tables, we can also see that the hygroscopicity (moisture regain) of traditional synthetic fibers is much worse than that of man-made fibers. However, it is not enough to conclude that synthetic fabrics are undesirable based on this table alone. Because after certain technical processing, such as 3M moisture absorption technology, even polyester fibers with an original moisture regain rate of only 0.4-0.5 can achieve very good moisture absorption effects.

The principle of 3M moisture absorption technology is to increase the micropores and surface grooves that communicate between the inside and outside of the fibril, making it easier for moisture to enter the fiber, thereby improving the fiber’s Moisture absorption rate. At the same time, because the grooves on the fiber surface have been opened, moisture can be transferred to the surface of the fabric and dispersed, allowing the moisture in the fabric to evaporate quickly, keeping it dry and non-sticky.

In addition to 3M of the United States, DuPont of the United States and Toyobo of Japan also have technologies that can modify the properties of polyester fibers and improve their moisture absorption and breathability, making traditional chemical fiber fabrics more durable. Meet the comfort needs of contemporary people.

Thanks to the fact that chemical fiber fabrics are tougher, more wear-resistant, lighter, and cooler, most international sports brand products are made of sex-modified chemical fiber fabrics. These chemical fiber fabrics not only have obvious advantages of their own, but they can also be blended with natural fabrics to improve the shortcomings of natural fabrics such as easy wrinkles and shrinkage to a certain extent! So, it’s time to change your inherent stereotypes about chemical fiber fabrics!

track=”69″>Thanks to the fact that chemical fiber fabrics are tougher, more wear-resistant, lighter and cooler, most international sports brand products are made of sex-modified chemical fiber fabrics. These chemical fiber fabrics not only have obvious advantages of their own, but they can also be blended with natural fabrics to improve the shortcomings of natural fabrics such as easy wrinkles and shrinkage to a certain extent! So, it’s time to change your inherent stereotypes about chemical fiber fabrics!