Identification of Lyocell fiber, Modal fiber, soy protein fiber, bamboo fiber, chitin fiber and milk protein fiber.

1. Lyocell fiber

Lyocell is a new generation of cellulose fiber. It adopts dry-jet wet spinning method and has a short production cycle. , the solvent is recycled, the production process is pollution-free, and it is a typical green and environmentally friendly fiber. Lyocell has the advantages of both natural and synthetic fibers. Its physical and mechanical properties are excellent, especially the wet strength and wet modulus are close to synthetic fibers. It also has the comfort of cotton fiber, the drape and bright color of viscose fiber, and the silk Soft feel and elegant shine.

2. Modal fiber

Modal fiber is also a new generation of regenerated cellulose fiber. Its fabric has hygroscopic properties, breathable properties, and dyeing properties. , dimensional stability and wrinkle resistance are better than pure cotton fabrics, soft to the touch, good drape, comfortable to wear, bright color, and natural mercerizing effect. At present, Modal fiber has developed a variety of functional products.

3. Soybean protein fiber

my country is the first country to industrialize the production of soybean protein fiber. Its raw material, soybean waste meal, is rich in resources, and the production process does not pollute the environment, human body, etc. Soybean protein fiber not only has the characteristics of small single filament fineness and low density, but also has a soft feel like cashmere, a soft luster like silk, the moisture absorption and moisture conductivity of cotton fiber and the warmth retention of wool.

4. Bamboo fiber

Bamboo fiber is a new type of regenerated cellulose fiber independently developed and industrialized in my country. It has many other Fibers have incomparable advantages, such as good spinnability, dyeability and moisture absorption and release. In addition, bamboo fiber has good natural antibacterial, anti-mildew, anti-moth and anti-ultraviolet functions, and is a good functional fiber. The biggest advantage of bamboo fiber fabric is that it is comfortable and cool, making it an ideal fabric for summer clothing and bedding.

5. Milk protein fiber

Milk protein fiber has biological health functions and natural long-lasting antibacterial effects. It contains a variety of amino acids. The fabric has the effect of moisturizing the skin when worn close to the body. Its texture is light and soft, breathable, moisture-conducting and refreshing. It is not as susceptible to mold or aging as other animal protein fibers.

6. Chitin fiber

Chitin and its derivatives are a type of natural polymer with diverse functions and wide uses. It is used in food, biology, medicine, textile, printing and dyeing, wastewater treatment and other fields. Especially in recent years, its applications have been continuously expanded due to its biocompatibility, low toxicity, biodegradability, and many medical functions and effects. Chitin fiber can be spun independently or blended with other plant fibers, coated, etc. The products maintain their original unique physical and chemical properties and biological characteristics. They are high-end green health-care textiles with excellent hygroscopicity, adhesion, and texture. Affinity, non-immune antigenicity, antibacterial and healing properties, etc.

Comparison of common properties of various fibers

Identification method

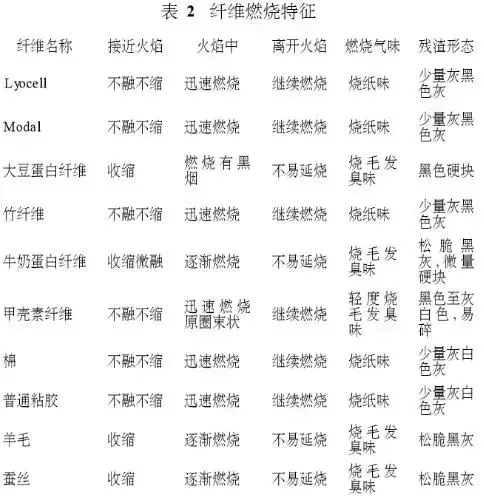

1. Combustion method

The combustion method uses the different chemical compositions and combustion characteristics of fibers to identify fibers. Through it, fibers can be divided into major categories, mainly cellulose fibers, protein fibers, and synthetic fibers. etc., to provide direction for subsequent further identification.

The method is to take a small amount of fiber, burn it with an alcohol lamp, and carefully observe the burning state, burning smell and final ash of the fiber when approaching the flame, in the flame and leaving the flame.

Through combustion, it can be seen that Lyocell, Modal, and bamboo fibers have combustion characteristics similar to cotton, linen, and ordinary viscose fibers, and are regenerated cellulose fibers. Soybean protein fiber and milk protein fiber have burning characteristics similar to wool and silk fibers, and are protein fibers. The combustion characteristics of chitin fiber are quite special and have some characteristics of both cellulose fiber and protein fiber.

The combustion characteristics of the six fibers are shown in Table 2, and compared with common cotton, ordinary viscose, wool, and silk fibers.

2. Microscopic observation method

Use a microscope to observe the longitudinal and cross-sectional morphology of the fiber, and identify the fiber according to its morphological characteristics.

Pull the fiber straight and parallel, take a small amount and place it on a glass slide, drop distilled water on it, cover it with a cover glass, and observe the longitudinal shape of the fiber under a microscope. Adopt��Milk fiber is smooth and has no micropores, while soy protein fiber is not smooth and has irregular bumps and micropores. When dimethylformamide is used as a solvent and heated to boiling, the milk fiber swells and other protein fibers remain unchanged, further distinguishing it from wool, silk, chitin fiber and soy protein fiber.

(6) Identification of chitin fiber (pure): Observe the combustion characteristics. It has the characteristics of cellulose fiber that does not melt, shrinks, and burns rapidly, but also has the smell of burning protein fiber, which is different from other fibers. What is surprising is that as soon as the fiber comes into contact with the flame, it quickly burns to black and keeps the shape of the original fiber bundle. It is easily brittle and continues to burn in the flame, and finally turns into a small amount of gray-white ash. From this, it can be initially estimated that it is chitin fiber. Observed under a microscope, there are pores and cracks on the surface of the fiber, which can be clearly distinguished from wool, silk and milk protein fibers, as well as Lyocell, cotton, bamboo fiber and ordinary viscose. Coloring with I-KI reagent is no different from Lyocel I, Modal, bamboo fiber and ordinary viscose in wet state. However, after drying, the iodine on the chitin fiber is most likely to sublime, causing the color to change from black, blue, blue to reddish brown. . When boiled with 5% sodium hydroxide as a solvent, the chitin fiber dissolves and can be distinguished from all other fibers except silk. When boiled with 88% formic acid, only chitin fiber can be dissolved and other fibers cannot be dissolved.