What is cupro fiber? Does it contain copper?

1. What is cupro fiber?

Cupper ammonia fiber,Many people may think it is a metal fiber, but in fact cupro fiber is a regenerated cellulose fiber. The English name is Cupro. It is a regenerated cellulose fiber obtained by dissolving loose cotton linters and other natural cellulose materials in a concentrated ammonia solution of copper hydroxide or alkaline copper salt to form a spinning stock solution, and then through the cupro-ammonia process. , named after the treatment with ammonia and copper hydroxide during the manufacturing process.

2. Characteristics of cupro fiber

1. Good dyeing performance

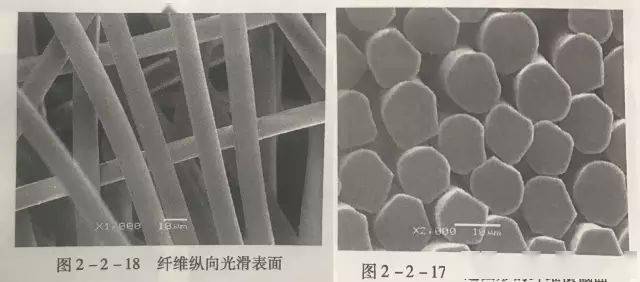

The longitudinal shape of cupro ammonia fiber has a smooth and shiny surface, and the cross-section is round or approximately round. shape. The fiber has good dyeing performance, bright dyeing, good color fastness, high dye uptake rate, not easy to fade and has good stability. Its fiber density is higher than silk, polyester, etc., so it has a very drapey feel;

1

Microscopic longitudinal morphology of cupro ammonia fiber

Microscopic cross-sectional morphology of cupro ammonia fiber

2

2. Good antistatic effect

Cupper ammonia fiber has a high moisture regain rate, second only to animal hair fiber and higher than cotton, linen and other chemical fibers. Because of its high moisture absorption and release efficiency and low specific resistance, it has better antistatic properties and is more comfortable to wear.

3. Delicate feel

When cupro ammonia fiber comes into contact with human skin, it feels soft and delicate, with a strong silky feel. Cupro ammonia fiber is safe and harmless to the human body. The processed imitation silk products have soft luster, bright color, elegant and smooth feel. Cool, elegant style. Cupro ammonia fiber has good durability, and the processed products have greater resistance to deformation and bending.

3

4

4. Good elongation

Cupper ammonia fiber has good elongation and returns It has good elasticity, good anti-fouling performance, good thermal insulation performance, good tensile elasticity and compression elasticity, large elastic recovery rate, and good stretch performance. The fiber has good fluffiness, and the processed products have good elasticity, full hand feel, good stiffness and anti-wrinkle properties, good shape retention after washing, and good dimensional stability.

5. Environmentally friendly

Since cupro fiber uses non-petroleum raw materials in the processing process, in the natural environment, the finished products and waste are easily decomposed by bacteria in soil and water, and there will be no decomposition even if burned. Toxic gases appear, so there is no damage to the ecological environment, and it is more environmentally friendly.

5

At present, the development of cuprammonium fiber is relatively mature and has evolved from Clothing linings are pushed to fabrics. Fabrics are not only unique in style, comfortable to wear, but also more environmentally friendly, so they are often used as raw materials for high-end clothing fabrics.

3. Introduction to cuprammonium fiber properties

Cuprammonium fiber

fiber) is a regenerated cellulose fiber. It is made by dissolving natural cellulose raw materials such as cotton linters in a concentrated ammonia solution of copper hydroxide or alkaline copper salt to form a spinning solution. The fiber is spun into a coagulation bath, and then in a second bath containing 2-3% sulfuric acid solution, the cuprammonium fiber molecules are chemically decomposed to regenerate cellulose. The resulting hydrated cellulose can be post-processed to obtain cuprammonium fiber.

The fabric made of cupro fiber has a soft feel, soft luster, and silk feel. Its wearing performance is relatively good, with good hygroscopicity and great drape. Its wearing performance is similar to that of silk, which is in line with the trend of environmentally friendly clothing.

Characteristics and properties of cupro fiber

Cupro ammonia fiber has a circular cross-section and no sheath-core structure. The fiber can withstand a high degree of stretching. The resulting monofilament is thin, generally below 1.33dtex (1.2 denier). Up to 0.44dtex (0.4 denier).

Fiber cross-section

1

Cupro fiber is 100% cellulose fiber, which is a green and environmentally friendly decomposable fiber. Because the raw material of cupro ammonia fiber is extracted from the short villi of cotton seeds in cotton, it is easily decomposed by bacteria in soil and water. It does not release toxic gases when burned, and the waste is easily decomposed, so it has environmental protection properties.

2

The cross-section of cupro fiber is approximately round, the surface is smooth, and the friction with the skin is small. In addition, after washing, cuprammonium fiber will not easily have detergent residue on the fiber surface, causing little irritation to the skin and being gentle to the skin.

3

Dyeing properties of cupro fiber Well, the dyes used for viscose fiber can also be used for cuprammonium fiber. The dyeing is bright, the color spectrum is complete, the color fastness is good, the dye uptake rate is high, it is not easy to fade, and the stability is good.

4

Cupper ammonia fiber has good hygroscopicity and can quickly absorb and discharge moisture emitted from the human body, suppressing the feeling of stuffiness and stickiness, and keeping the clothes inside. Adjust the humidity to a comfortable level to provide a refreshing feeling in all seasons.

Cupro ammonia fiber has a high moisture regain, and its hygroscopicity is close to that of viscose fiber. The official moisture regain is 11%.

4. Identification of cupro fiber and lyocell fiber

strong>

Both cupro fiber and lyocell fiber are regenerated cellulose fibers. Their molecular structure is similar to cotton, and they also have features that cotton fiber does not have. The advantages of silk, such as dryness, smoothness, comfort and coolness, have great application value in the field of textile and clothing. Due to the great similarity in appearance and chemical structure between cupro fiber and lyocell fiber, conventional methods such as microscopic observation, burning and dissolution of fibers cannot identify these two fibers.

1. Similarities

Cross section of cupro fiber

Lyocell fiber cross-section

Cupro ammonia fiber and lyocell The cross-sectional shape of Sayer fiber is similar, with a circular cross-section and a smooth and shiny longitudinal cross-section. At the same time, both fibers are regenerated cellulose fibers with the same chemical composition and basic structural unit, which is cellulose.

Therefore, the combustion phenomenon and chemical dissolution are also similar, and conventional methods such as microscope observation, combustion and dissolution cannot identify this Two types of fiber.

2. Identification method

1

Organizational structure differences

Lyocell fiber has a skin-core structure. The skin structure is dense and thin, easy to be damaged, and is close to a full-core structure. Obvious fibril structure, especially the oriented crystalline arrangement along the fiber axis is very high;

Lyocell fiber in liquid state When the fibers expand laterally, the lateral bonding force between fiber fibrils is greatly weakened. Under the action of mechanical external force, the fibrils are separated from the fiber surface, resulting in fibrillation phenomenon.

Cupper ammonia fiber has no skincore structure and is not prone to fibrils phenomenon.

Using fibrillation properties to distinguish lyocell fiber and cupro fiber, pointing out that lyocell fiber can be distinguished by microscopy and cuprammonium fiber, but research shows that this method is only suitable for the rough identification of fibrillated lyocell fiber and cuprammonium fiber, and is not suitable for the identification of non-fibrillated lyocell fiber and cuprammonium fiber.

2

Fiber strength

The average polymerization degree of cupro fiber is 450~500, and the strength is slightly lower than that of laminate Cell fiber.

Lyocell fiber has an average degree of polymerization of 500 to 550. The molecules are compact and regular, with high intermolecular forces and fiber strength. Also larger.

3

Copper ion content analysis

Copper ammonia fiber during spinning During the process, I have been exposed to higher concentrations of copper ions. Although the copper ions have been removed by dilute acid treatment, they still contain relatively more traces of copper ions than other fibers.

Testing the copper ion content of the two fibers can be used as an auxiliary method to identify the two fibers. However, since the copper ion content in textile materials is affected by various factors in the dyeing and finishing process, such as the dyes, slurries used, especially finishing additives, this identification method has certain limitations.

4

Near-infrared spectroscopy analysis

Near-infrared spectroscopy (NIR) It is an electromagnetic wave between visible light (VIS) and mid-infrared light (MIR or IR). The American Society for Testing and Materials (ASTM) defines the near-infrared spectral region as the spectral region with a wavelength of 780 to 2526 nm (wave number is 12820 to 3959 cm-1) .

Although cupro and lyocell are both regenerated cellulose fibers, they use different raw materials. You can try Use near-infrared spectroscopy analysis method to characterize the difference between the two.

5

X-ray diffraction analysis

X-ray diffraction method is a research An analysis method of information related to the atomic lattice of crystals, etc. The premise of this analysis method is that the atoms in the sample are arranged regularly, that is, it has a crystal structure.

For fibers, the crystallization conditions of fibers produced by different raw materials and different spinning processes are also different, which is reflected in There are different main characteristic diffraction peaks in the X-ray diffraction pattern.

Cupro and lyocell fibers use different raw materials and spinning processes, so that the average quality of the two fibers The degree of polymerization, crystallinity and orientation are all different. You can try to use X-ray diffraction analysis to characterize the difference between the two.

��3959cm-1).

Although cupro and lyocell are both regenerated cellulose fibers, they use different raw materials. You can try Use near-infrared spectroscopy analysis method to characterize the difference between the two.

5

X-ray diffraction analysis

X-ray diffraction method is a research An analysis method of information related to the atomic lattice of crystals, etc. The premise of this analysis method is that the atoms in the sample are arranged regularly, that is, it has a crystal structure.

For fibers, the crystallization conditions of fibers produced by different raw materials and different spinning processes are also different, which is reflected in There are different main characteristic diffraction peaks in the X-ray diffraction pattern.

Cupro and lyocell fibers use different raw materials and spinning processes, so that the average quality of the two fibers The degree of polymerization, crystallinity and orientation are all different. You can try to use X-ray diffraction analysis to characterize the difference between the two.