Fiber

(1) Cotton fiber

Cotton fiber is The fiber without cotton seeds is called lint or raw cotton and is an important raw material for textiles. According to the thickness, length and strength of the fiber, raw cotton can generally be divided into the following three categories.

(1) Long-staple cotton. Long-staple cotton, also known as sea-island cotton, is a slender, mercerized, high-strength cotton fiber. It is an important raw material for spinning high-end and special cotton textiles.

(2) Fine velvet cotton. Fine velvet cotton, also known as upland cotton or plateau cotton, is a natural textile fiber with a wide range of uses. It is the most widely planted and has the largest output in the world.

(3) Coarse staple cotton. Coarse cotton, also known as Asian cotton, is the earliest textile fiber used in my country. Coarse cotton has thick fibers, short length, and good elasticity. It is suitable for making pile yarn, making flannel fabrics or batting, etc.

Common fiber characteristics

(2) Hemp fiber

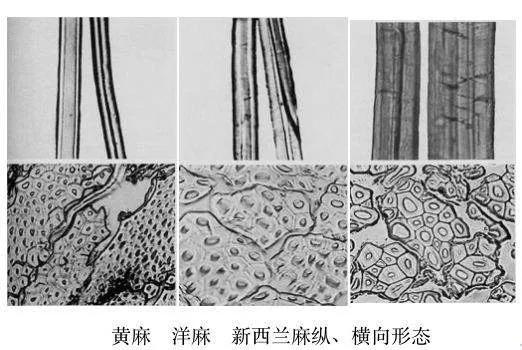

Hemp fiber is made from Fibers obtained from various hemp plants, including bast fiber and leaf fiber. Hemp fiber is one of the earliest textile raw materials used by humans for clothing. There are many varieties of hemp fiber. Ramie, flax, jute, hemp, apocynum, sisal, etc. are often used as raw materials for clothing textiles.

(1) Ramie. Ramie is the best textile raw material among hemp fibers. Ramie fibers are thicker and longer, so they can be spun into thinner yarns. Ramie fiber can be pure or blended. Ramie fiber can be blended with polyester to make summer clothing. It is light, cool, crisp, not close to the body, has good breathability, and is easy to wash. Ramie fiber feels harder and the yarn has more hairiness.

(2) Flax. Flax is also the best textile raw material among hemp fibers. The length of flax fiber is shorter than that of ramie fiber, and its fineness is finer than that of ramie fiber. Flax fiber feels thicker and harder than cotton fiber, but softer than ramie fiber. Flax fiber can be either pure or blended, usually blended with ramie, cotton and chemical fibers. It is a very good clothing material and is also a fabric for embroidered or embroidered clothing.

(3) Other hemp fibers. In addition to the most commonly used ramie and flax fibers, hemp fibers used in clothing materials include apocynum, jute, hemp, etc. Apocynum fiber is relatively soft and has health care value; fibers such as jute and kenaf are thicker but have good moisture absorption and breathability, so they are suitable for packaging materials.

Fiber form

(3) Silk fiber

Silk fiber among natural fibers refers to silk fiber, which is the only natural fiber Long fiber, the general length can be between 800 and 1100m. They are the main raw materials of satin. Silk fiber comes from tussah, mulberry silkworm, castor silkworm, cassava silkworm, etc., with mulberry silkworm having the best quality.

(1) Mulberry silk. Silkworms belong to the family of silkworms. Silkworm breeding has a long history in our country.

Mulberry silk, also called real silk, is a high-end textile raw material. According to different processing methods, it can be divided into two types: raw silk and cooked silk. Raw silk is hard, cooked silk is soft. Raw silk is unrefined silk, that is, silk that has not undergone any treatment after being reeled. The silk reeled by the native method is called native silk (which has been basically eliminated); the silk reeled by the improved method (semi-mechanized) is called worker and peasant silk. Gongnong silk is the raw material of Hangfang, Shaofang, Hangluo and Shaoluo; silk reeled with perfect mechanical equipment is called factory silk. Factory silk has good quality, uniform thickness and good gloss. Ripe silk refers to silk that has been refined.

(2) Tussah silk. Tussah silkworms are wild silkworms that feed on tussah leaves. my country’s four provinces of Liaoning, Shandong, Henan and Guizhou are the main producing areas and are world-famous producing areas. The color of tussah is yellowish brown. This brown pigment is difficult to remove, making it difficult to dye it into a beautiful color, which affects its use value.

(3) Double uterine wire. Double palace silk is made from double palace cocoons. Double palace cocoons are two silkworms making a cocoon, and the two silk heads are twisted together in a disorderly manner. The extracted silk has different tightness and thickness, and there are many small bumps on the silk. However, it is precisely because of this shortcoming that it causes This kind of silk fabric is thick and unique, and is very popular in domestic and foreign markets.

(4) Silk. Spun silk is made from waste silk, waste cocoons, cocoon clothing, etc., which are processed into short fibers and then spun into yarn through the spinning process. The silk has excellent luster, uniform thickness, good strength and elongation. Because it is made of short fibers, there is a lot of air in the threads, and it has good thermal insulation properties and good hygroscopicity. It is suitable for pajamas fabrics, etc. Its disadvantage is that it is easy to get lint after repeated washing.

(5) Silk. Silk is inferior to spun silk. It is spun from the leftover silk and cocoon lining left over from spun spun silk. This kind of raw material has many pupa chips, uneven yarn thickness, and poor luster, but has a rough style and a soft feel.

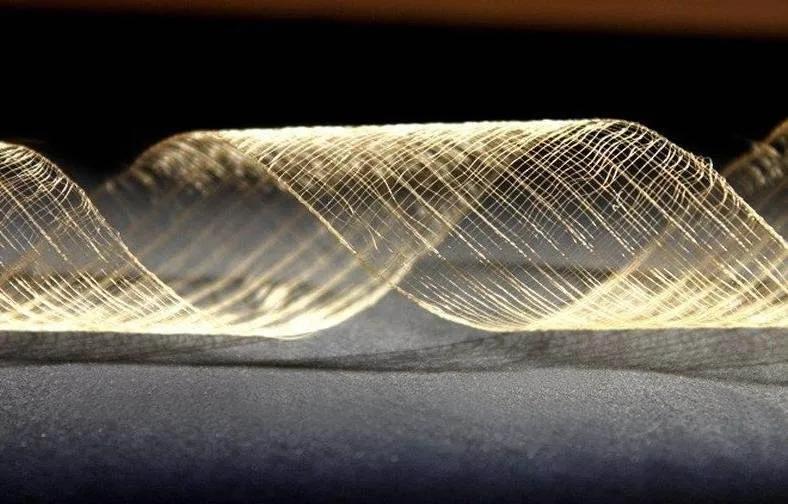

Dyeing thread

<p data-track="9

Vinyl is as white as snow and as soft as cotton, so it is often used as a substitute for natural cotton. People call it synthetic cotton. It has the best hygroscopicity among synthetic fibers. Secondly, it has good wear resistance, light resistance and corrosion resistance.

Vinyllon has a skin-core structure (like the wood core layer of a pencil), and its cross-section is kidney-shaped. Due to its skin-core structure, it brings greater difficulty to dyeing. Big difficulty. Its resilience is poor, so fabrics produced from it are prone to wrinkles. In addition, vinylon has another major feature: strong resistance to dry heat, but extremely poor resistance to moisture and heat. Currently, vinylon products are rarely used in clothing.

(5) Polypropylene. The scientific name of polypropylene fiber is polypropylene fiber, and it is called polypropylene fiber and polypropylene fiber abroad. Polypropylene is one of the youngest varieties of synthetic fibers. Fabrics containing polypropylene are stiff and elastic, and also have good warmth retention, water resistance, and corrosion resistance.

Clothes made of polypropylene are not breathable and feel stuffy when worn, but the fabric shrinks very little and is easy to wash and dry. Polypropylene has poor light resistance and heat resistance, and the ironing temperature should not exceed 100°C. Polypropylene also has poor hand feel and is not easy to dye. Polypropylene is rarely used in clothing and is often used in padding and carpets.

(6) Chlorine. The scientific name of chlorine fiber is polyvinyl chloride fiber. Most of the plastic ponchos, plastic shoes, etc. that we come into contact with in our daily life belong to this kind of raw material. Abroad, it is known as Tianmeilun and Rowell.

Chlorine fiber has many advantages, including strong chemical corrosion resistance and easy storage; thermal conductivity is worse than wool, but it has strong thermal insulation; it has high electrical insulation and is flame retardant. The disadvantage is that it has extremely poor heat resistance and is rarely used in clothing.

(7) Spandex. The scientific name of spandex is polyurethane elastic fiber. It is a chemical fiber with special elastic properties. It has been industrially produced and has become the fastest growing elastic fiber.

Spandex has good acid and alkali resistance, sweat resistance, seawater resistance, dry cleaning resistance, and abrasion resistance. The moisture regain of spandex is 0.

Spandex mainly exists in fabrics in the form of core-spun yarn, or it can be made into deformed yarn with spandex to weave elastic fabrics. Common ones include stretch jeans, stretch underwear, and stretch fabrics. Swimming suits, fitted fashions, etc.; used in woven and knitted fabrics, with the ability to fit and stretch; widely used in socks, gloves, collars, cuffs of knitwear, belts and tight-fitting parts of space suits.

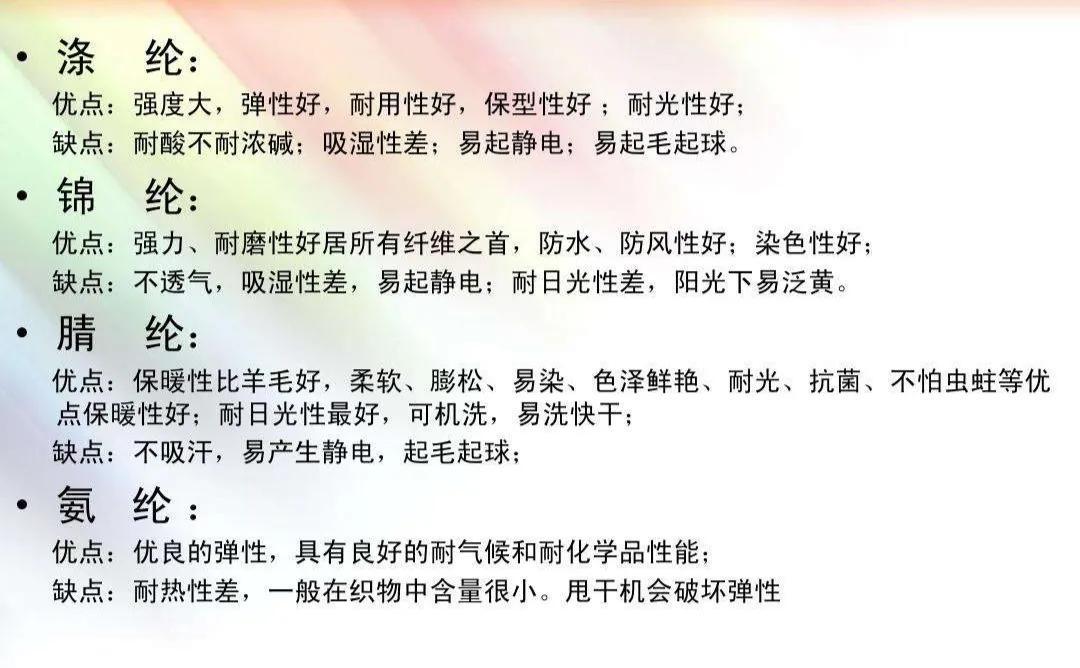

Comparison of fiber advantages and disadvantages